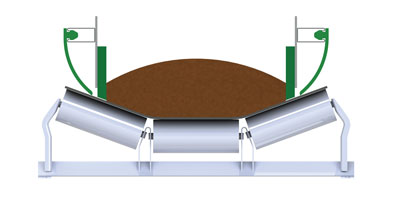

Argonics’ Snap-Loc dust seal and containment liner work in harmony to provide a cost-effective, efficient material containment and dust control solution for troublesome transfer points. According to Argonics, the pairing quickly transforms the most chaotic areas in a plant into much cleaner, safer and virtually maintenance-free transfer points. Using Snap-Loc and containment liners together increases productivity and reduces downtime, the company says. The two products are designed to fit and easily install on most conveyor systems on the market.

Protect vital processing equipment with suspended magnets

Eriez CP-20 and TP-25 suspended permanent magnets can be installed upstream on crushers and other size-reduction equipment. According to Eriez, the expense of magnets is easily justifiable when considering that the magnet’s price point is significantly less than the cost of downtime and repairs associated with damage to essential equipment. Eriez suspended magnetic separators are most effective for the removal of unwanted iron from heavy burdens of bulk materials being transferred on conveyor belts. The safe and reliable tramp iron removal provided by the magnets safeguards processing machinery and assures the purity of the product, the company says.

Modular transfer chute addresses installation downtime

Martin Engineering introduced a modular transfer chute for belt conveyors, reimagining the bulk handling transfer chute to reduce downtime for installation and offer options for future modifications. The new Martin transfer point kit includes modular horizontal loading zone, settling zone and stilling zone configurations. The development provides what Martin Engineering describes as easier installation and a wider variety of chute options while facilitating future upgrades. Martin Engineering’s kit reduces the amount of labor required for assembly and allows the system to be pre-built prior to installation for reduced system downtime.

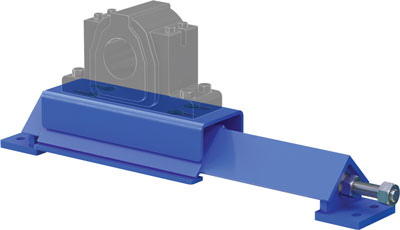

The advantages of take-up frames are aplenty

Martin Sprocket & Gear says its take-up frames keep employees safe while extending conveyor belt life and increasing yield. A belt conveyor that is properly designed with take-up frames can deliver several benefits to both employee safety and conveyor system maintenance. According to Martin, maintaining proper tension on a belt is crucial to prevent inefficiencies caused by belt slippage at the drive pulley and reduce belt sag, which can affect the life of the belt and components. Additionally, the company says Martin take-up frames can provide tension to belts throughout a conveyor system, extending the life of the belt, reducing maintenance costs and increasing yield.

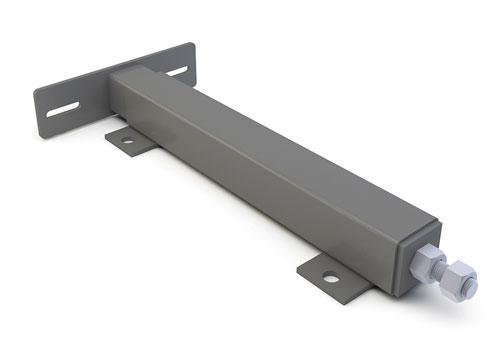

Custom designed and made for the industry

PPI (Precision Pulley & Idler) offers a number of different styles and options in take-up frames, which eliminate the need for additional take-up supports and enable load distribution. PPI’s precision slide tube (PST) take-up frames are its most popular, featuring a design that protects the screw from the environment. According to PPI, different take-up frame styles provide tension to the return side of conveyor belts. PPI offers an extensive line with characteristics that make them rugged and easy to operate and install.