Exterra belt cleaners from Superior Industries are created with a urethane blade, featuring models that are available in both aggregate and mine-duty constructions. Blade widths are available up to 102 in., the company says, and a fast-acting click tensioner is available for the primary and secondary Exterra models. Following installation, operators twist the tensioning unit a prescribed number of times to set the proper force. Click-count instructions are labeled on an aluminum housing that protects the springs.

Drum motor design addresses safety, efficiency and productivity

GrizzlyDrive drum motors are built for demanding belt conveyor applications with high-quality, precision-made components, according to VDG (Van der Graaf). They’re designed to withstand harsh, abrasive and dusty environments. All GrizzlyDrive components, including the electric motor, gear reducer and bearings, are enclosed and protected from the environment. The VDG oil cooler/conditioner delivers consistent and optimal oil viscosity and temperature to all drive components, VDG adds, ensuring the longevity and performance of the drum motor. GrizzlyDrive drum motors are available up to 500 hp and supplied with the VDG oil cooler/conditioner as standard for all drum motors 75 hp and up.

Protective coupling provides cushioned start, energy savings

Flux Drive’s SmartCoupling technology is designed with a belt pulley adapter (FSC-BP) that offers a cushioned start and energy savings for belt-driven loads. According to Flux Drive, the FSC-BP is designed as a slide-on replacement for existing motor pulleys, providing a 100 percent mechanical cushioned start for fans, blowers and other belt-driven loads. The FSC-BP uses permanent magnets to transfer torque across the air gap by means of magnetic induction. According to Flux Drive, SmartPower air gap spacers can be easily inserted to decrease the magnetic coupling effect of the SmartCoupling, giving operators the ability to extend cushioned-start duration and reduce the fixed operating speed by up to 50 percent on 1,800-rpm applications.

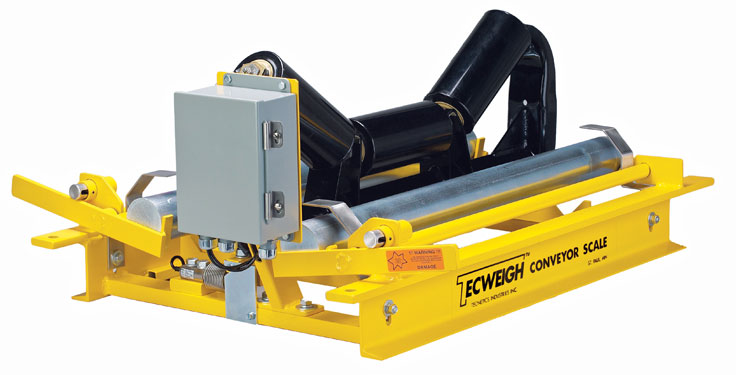

Belt scales with accuracy offer durability, reliability

Tecweigh’s WY15, WY25 and WY45 belt scales feature single-, dual- and four-idler versions to meet or exceed accuracy requirements. Self-storing calibration weights make routine checks easy and safe. Plus, the weights can be found mounted in the belt scale frame. According to Tecweigh, these scale systems are built for the harsh conditions commonly encountered in aggregates and mining.