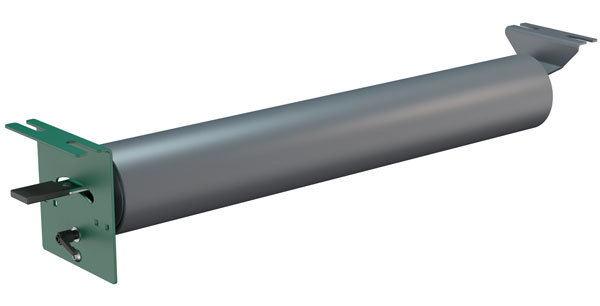

A return training bracket from Precision Pulley & Idler (PPI) provides users with a solution to knock idlers and reduce labor. According to PPI, its design allows the drop bracket to remain bolted to the conveyor framework while allowing for easy roll adjustments. By strategically positioning return training brackets in a conveying system, PPI says users can easily train a belt as conditions change within the application. The return training bracket will interchange with PPI standard CEMA B, C and D return rolls with 4 1/2-in. drop brackets.

Stockpile materials in set patterns

The TR-80 radial conveyor from Finlay can be integrated into static operations or mobile crushing and screening setups in a range of applications. One feature is an automated stockpile program that allows operators to stockpile materials in set patterns to suit their operations and site configuration. Adding to its adaptability, Finlay says the radial functionality allows for flexible stockpile configurations, catering to various material types and site layouts. When operated in conical mode, the TR-80 has a maximum discharge height of 33 ft., 5 in. The radial conveyor can stockpile 2,369 cu. yd. of material, Finlay says.

More protection for rotating equipment

The model RMS-G is a zero-speed control that can provide protection to various types of rotating equipment, according to Conveyor Components Co. The RMS controller uses an inductive proximity sensor and a ferrous target disk affixed to the end shaft to determine if a piece of equipment is rotating or if it has lost motion. The RMS controller now incorporates some of the latest advances in electronic technology, the company says, including surface-mount componentry. This allows the circuit board assembly to be lower in profile, lighter in weight and reliable in operation.

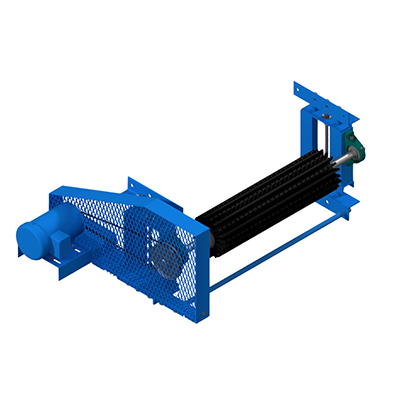

Enhance production, safety with belt tracker

The Tracker HD tracking device for belt conveyors features upper and lower units that provide immediate, continuous and precise adjustment of mistracking belts. According to Martin Engineering, the result is greater productivity with less unscheduled downtime related to equipment replacement and spillage cleanup for a lower cost of operation. The Tracker HD is suitable for belt thicknesses up to 1.125 in. and speeds up to 800 ft. per minute. Both the upper and lower units accommodate belt widths of 36 to 72 in. with an effective tracking distance of 150 ft., according to the company.