Author

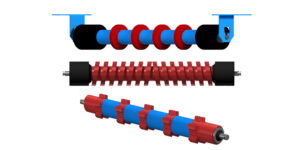

Luff Industries: Urethane Return Rollers

Luff Industries has introduced a variety of urethane products to its product lines, including several return roller options. The Urethane Return Rollers offer efficient cleaning, belt friendly designs that outlast and outperform rubber return rollers up to 5 times. Clean Weave spiral design cleans the bottom side of the conveyor belt through an augering action. The roll discs are always contacting the belt in a new area increasing the cleaning action. The Urethane Beater Return Roller effectively cleans the belt and is engineered to be safe for cleated belts. For more information about Luff’s Urethane Return Rollers please contact us today! Learn more Keep Reading

Deister super-duty inclined screen delivers greater reliability & cost savings

In asphalt batch plants, the Deister UHS inclined screen is typically mounted atop the hot bins. This super-duty machine is designed to withstand high temperature feeds while isolating the vibrating motion from the structure via a patented steel and rubber spring suspension system. A stationary dust enclosure contains free dust. A key benefit to the screen is its higher production due to increased screening area. The unit is equipped with a full-length sand screen that provides maximum screening area on all decks. Cost-saving technology For operating cost savings, the Deister System Saver is added to the batch plant screen. Without exposing oil to the open environment, the System Saver filters out harmful contaminants in the lubricating oil, allowing reuse of the oil. Importantly, it extends the life of the antifriction bearings in the lubrication system, while reducing costly bearing replacement, system downtime, and oil disposal costs. Learn more Keep Reading

Polydeck: Falling Short Of Production Targets – And Not Sure Why?

When throughput dips or downtime creeps in, it may be worth considering whether the vibrating screen needs to be evaluated. Even when screen media is performing as expected, mechanical factors like stroke settings, alignment, or structural wear can quietly affect efficiency. That’s where PRO ANALYSIS comes in. Our Screening Expert inspects the vibrating screen, evaluating stroke settings, alignment, structural integrity, and operating parameters to identify machine-related inefficiencies that may be affecting your operation. ✅ Identify machine-driven bottlenecks with real diagnostic data✅ Improve screening consistency and reduce unplanned downtime✅ Protect downstream equipment and maintain KPI alignment✅ Get clear, actionable insights to bring to your OEM or maintenance team—no guesswork required Learn more about our PRO Analysis service today Keep Reading

Superior Industries: Sentry Horizontal Shaft Impactor (HSI)

Getting the most out of your horizontal shaft impactor (HSI) starts with matching the right machine to your material and end goals. That’s why Superior offers a complete line of Sentry® HSI models, each engineered for specific applications in aggregate production and recycling.For primary crushing, the rugged SP models handle up to 40-inch feed and are available in multiple rotor configurations. Secondary crushing is covered by the versatile SS models, which offer a grinding path option for added reduction when needed. And for recycling jobs with tricky material like rebar or slabby concrete, the enclosed-rotor SR models are built to keep tramp iron from tangling things up.Across the board, Sentry HSIs are designed to reduce downtime, adapt to varying applications, and deliver consistent performance. Learn more Keep Reading

Steel Warehouse: Durable Steel Solutions

Steel Warehouse understands the unique challenges of the aggregate and mining industry — and we’re here to help. We have a range of durable steel solutions to maximize your equipment’s performance. Our high-strength steels, up to Grade 160, reduce equipment weight, while also increasing payload capacity for haul trucks, excavators and other mining vehicles. Our abrasion-resistant steels, up to AR500, offer excellent wear and impact characteristics, minimize downtime and improve productivity. Learn more Keep Reading

VDG (Van der Graaf): Maintenance-Free GrizzlyDrive Series Drum Motors

VDG’s GrizzlyDrive® Drum Motors are designed to endure the demands of belt conveyors operating in mining and aggregate industries. All drive components, including the electric motor, gear reducer, and bearings, are enclosed within the drum, designed for 80,000 hours of continuous operation before maintenance. The Belt Cleaner is a VDG Drum Motor that has a replaceable spiral brush mounted on the drum. The VDG Belt Cleaner cleans the belt without wear or damage, increasing the life of the belt and reducing operating costs. Learn more Keep Reading

Kleemann MOBISCREEN EVO: Precision Quality in a Flexible Package

Changing work sites and new applications often create challenges for screening plants. The mobile screen for coarse elements on the Kleemann MOBISCREEN is ideally prepared for this. With their flexible conversion options, the best material flow can be guaranteed for the harshest of elements in your natural stone and recycling applications. The screen casings of the MOBISCREEN EVO plants, with an area of 7 or 9.5 m², are also designed for high outputs. An optimum distribution of the material on the screening surface is guaranteed by adapting the screening angle to the material. The feed hopper makes an optimum material flow possible thanks to its very large holding capacity and the opening width in material flow direction. Find Out How MOBISCREEN Can Change Your Jobsite Keep Reading

AZFAB High Rate Thickener-Clarifier

The AZFAB Thickener-Clarifier recycles water by separating the liquid from the solids. Thickener concentrates the sand, and clarifies the water. Keep Reading

General Kinematics’ Portable Horizontal Screen

Power up your productivity with General Kinematics' Portable Horizontal Screen—your ultimate solution for efficient, on-the-go screening. Designed with flexibility in mind, this rugged machine adapts to your specific material and process needs. Completely customizable and built to endure the toughest conditions, it delivers precision performance wherever the job takes you. This screen keeps your operation moving and your profits growing. Don’t wait—experience the future of screening. Contact us today and let’s build the perfect solution for you. Learn more Keep Reading