Author

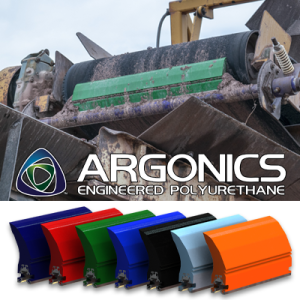

Argonics Replacement Blades

Most Argonics polyurethane replacement blades have a one-week lead time! Argonics blades fit most OEM systems, and they outlast any other polyurethane blade by a 2-to-1 margin. Argoncs’ blades are the only belt cleaning blades in the world made with Kryptane® polyurethane, the most abrasion-resistant, longest-wearing urethane available. The Argonics primary and secondary replacement blades are specifically engineered to eliminate carryback by removing debris from the belt’s surface. They are field-tested and proven to withstand the most severe conveying environments around the world. Contact us today to find out more! Keep Reading

Nobel Fire by Dyno Nobel

Nobel Fire® by Dyno Nobel is a digital platform that offers best-in-class software solutions for quarries of all sizes. Air and ground vibration are major areas of concern at most quarries, and Nobel Fire offers key tools to predict and mitigate vibration. Its Advanced Vibration Prediction tool uses a unique waveform generation algorithm to provide vibration prediction with industry-leading accuracy. It pairs seamlessly with the Vibration Timing Optimization tool, a signature waveform convolution engine that quickly helps identify blast timing pairs that help reduce vibration at a structure. By using these tools and the many other functionalities Nobel Fire has to offer, quarries and aggregates operations can improve their blasting while reducing costs. Learn more. Keep Reading

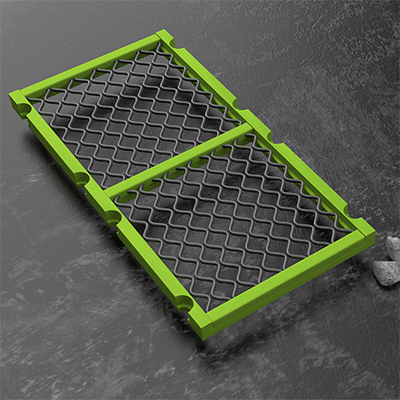

MAJOR FLEX-MAT Modular PLUS

MAJOR offers FLEX-MAT Modular PLUS, which is specially designed to withstand harsh screening conditions with the most abrasive materials, such as granite and basalt. Keep Reading

Regal Rexnord: Reliability in the Toughest Conditions

Regal Rexnord™ creates a better tomorrow with sustainable solutions that power, transmit, and control motion in the asphalt and aggregate industries. Built to last, our solutions are designed to endure in the harshest environments, keeping systems running in mission-critical applications. Our world-class portfolio of brands includes names you know and trust. Long-lasting and heavy-duty gearboxes including the Falk® Quadrive® and Rexnord® Planetgear™ are trusted gearing solutions for both asphalt and aggregate applications. No matter the bearing style or application need, we have a large selection of high-quality bearings and accessories from Link-Belt®, Rex®, Duralon®, Sealmaster®, and Rollway®. Safer, faster, and easier to install, RexPro™ Engineered Steel Chain is our newest industrial chain solution, and a complement to our existing engineered, welded, and roller chains. TB Wood’s® and Browning® belt drives and CENTA® and Stromag® couplings provide the durability needed in your drives. To keep all this running, Regal Rexnord Perceptiv™ intelligent reliability solutions apply 135 years of industry and application knowledge to predict and prevent costly downtime. Our expert engineers… Keep Reading

Weir Sandmaster Sand Wash Plants

Weir’s range of Sandmaster™ sand wash plants feature industry leading materials technology, process equipment and are fully supported by Weir Minerals’ unrivalled global service network. These plants contain our advanced technology and are designed to be portable, easy to assemble, maintain and operate. Weir Sandmaster™ sand wash plants are capable of meeting the needs of even the most experienced of sand producer while proving intuitive and easy to operate for a new entrant. Weir Sandmaster™ sand wash plants yield drier product and fewer moving parts compared to sand screw plants. They boast low energy consumption, maximum recovery, low total cost of ownership, and rapid assembly. Constructed using world-class components such as Warman slurry pumps, Cavex hydrocyclones, Isogate slurry valves, and Linatex® premium rubber, Weir Sandmaster™ sand wash plants feature compact skid design and flexible platform and stairs configurations. The VFD can reduce the plant’s overall power consumption and commissioning time, while increasing the wear-life of the pump. All discharge and connection points are designed to be operated with ease, and… Keep Reading

BKT USA Earthmax SR 41

The Earthmax SR 41 is an all-steel radial tire perfect for articulated dump trucks, loaders, and dozers. Thanks to its all-steel structure and special block pattern, EARTHMAX SR 41 provides excellent resistance against punctures and an extended service life. In addition to long working hours without downtime, the tire ensures extraordinary comfort. EARTHMAX SR 41 is also available in E4**** for low profile dump trucks (LPDT) used in underground haulage operations. About BKT For over 30 years, BKT has led the way in the creation and manufacture of safe, innovative, and performance-focused tires for a range of specialist sectors, including the construction, earthmoving, port, mining, and agricultural industries. Learn more. Keep Reading

MOTION Bearings for Harsh Environments

Available from Motion, Timken Type E housed units feature industry-leading premium tapered roller bearings, high-performance seals, e-coated housings and locking collars. The enhanced design and materials improve performance in the most severe applications—resulting in increased uptime, lower maintenance costs, and overall lower cost of ownership. The high-performance seals feature better grease retention; less contaminant ingress; and better protection against water, mud and salt ingress. The collar has maximum corrosion resistance, provides better locking strength, and cuts down set screw backout. The housing resists corrosion better than black oxide or powder coatings and features interchangeable bolt holes and shaft centerline dimensions. Learn more. Keep Reading

Unified Screening & Crushing: Square Opening Screening Media

Unified knows: an accurate square opening is critical. If you don’t meet spec, you might not get paid on a project. We want you to get paid on EVERY project. We stock the largest inventory of square opening screening media across the country. Got a question about changing your screen media and still meeting spec? Ask for Unified. Manufacturing all of our woven wire here in the U.S. Can your screen manufacturer say that? Info@unifiedscreening.com 800-332-6463 Learn more. Keep Reading

Superior Industries Chevron Wing Pulley

Unveiled with a modified design, Superior's CEMA and Mine Duty model Chevron Wing Pulleys no longer include a rounded cap on its wings. The alteration not only economically benefits Chevron Pulley owners, but also extends the service life by providing more wearable material on the bare wings. Originating in 2007, Superior's v-shaped Chevron Pulley revolutionized wing performance by deflecting fugitive material, minimizing rock entrapment, preventing belting punctures, reducing noise through constant pulley-belt contact, and proving gentler on belt splices and clips. This evolution marks a significant advancement in conveyor technology, aligning with Superior's commitment to enhancing conveyor system reliability and performance. Learn more. Keep Reading