Author

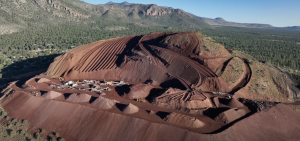

Exclusive look at Sheep Hill Cinder Mine with Juve Pinedo

[Sponsored Content] Juve Pinedo and his team have been exclusively retained to market and sell the fully operational Sheep Hill Cinder Mine in Flagstaff Arizona. Keep Reading

Cardinal Scale’s ARMOR Digital Truck Scale

Cardinal Scale’s ARMOR® Digital Truck Scale is not like other truck scales. It is an advanced digital system that is top-to-bottom different (and superior) to your grandfather's truck scale. From the manufacturer of the very first all-steel truck scale comes the state-of-the art ARMOR digital truck scale with SmartCell® load cells loaded with benefits. ARMOR truck scales feature 135-ton capacity, 50-ton CLC (concentrated load capacity), no moving parts below the scale deck including the load cells, more structural steel than the competition, SmartCell stainless steel waterproof digital load cells, baked-on tan powder coat paint, and iSite remote monitoring software. I-beams run from head plate to head plate throughout the weighbridge, so there aren’t structural weak points around load cell pockets like in competitor’s truck scales, which can lead to breakages. Learn more. Keep Reading

TerraSource Global Jaw Crushers

Our Pennsylvania Crusher™ line of Jaw Crushers are designed to reduce unusually hard, tough and/or abrasive rock and other materials such as ferroalloys and glass — materials which cause excessive wear to other types of crushers. The double toggle crusher is superior to both the standard Blake and the single toggle jaw types, typically found in the aggregate industry, due to its ability to crush strictly by compression without the inefficient rubbing action present in other crushers. The swing jaw meets the material squarely and compresses it directly against the stationary jaw plate. There are neither elliptical nor vertical motions involved reducing the abrasion or gouging of the jaw plates. This more efficient design also results in relatively low fines production, and because there is no lifting of the jaw, it permits virtually all the power to be used for crushing. Learn more about our Jaw Crushers and Vibrating Screen solutions that TerraSource Global’s flagship brands: Gundlach Crushers, Jeffrey Rader, Pennsylvania Crusher, and Elgin Separations Solutions offer. Learn more. Keep Reading

Stedman Introduces the Grand Slam Asphalt Recycler HSI

Stedman Machine Company introduces the newest machine in their product line up, the Grand Slam™ Asphalt Recycler. Crushing action of the SAR50 and SAR100 models allows for highly efficient RAP reclamation in one pass. With feed size up to minus 12” and capacities up to 100 TPH, this asphalt recycler reclaims ripped and milled asphalt breaking the pavement into usable, correctly sized recycle product. With Stedman's industry leading HSI rotor design, the Grand Slam Asphalt Recycler requires minimal daily maintenance and reduces labor costs through an auto-lube option. Capacities for recycling asphalt range between 40-100 TPH. Learn more. Stedman Machine Company, 812-926-0038 Keep Reading

Weir Enduron Orbital Screens

The all-new Weir Enduron® Orbital range of Sand and Aggregate screens feature an all-bolted construction that improves reliability by eliminating welding in high-stress areas. Delivering exceptional performance and service life, our screens are engineered with the widest operating window in the industry, allowing screen settings to be adjusted as operating conditions change. Individual components can be easily replaced thanks to the modular screen construction. Inventory holding is also significantly reduced through an approach that takes advantage of parts commonality throughout our screen range. To learn more about Enduron® Orbital screens, visit us at https://www.global.weir/product-catalogue/screening-equipment/. Keep Reading

Motion: Climax Metal Products

Mining machinery is constantly subjected to some of the harshest environments and torturous loads for which an engineer can design. Climax Keyless Locking Devices (KLDs) provide high torque, bending and axial thrust capacities and eliminate axial movement during installation. KLDs provide a mechanically designed system that eliminates the need for keyways, reducing downtime and loss of profit while allowing smaller shafting and components. They deliver a longer life for both mine duty and engineered class conveyor pulleys. KLDs are installed and removed using simple hand tools, enabling easy field serviceability. Learn more. Keep Reading

VDG New Premium-Efficiency GrizzlyDrive Drum Motors

Designed for belt conveyors operating in extreme and abrasive environments where performance, reliability, and durability matter most, the GrizzlyDrive® Drum Motor features a heavy-duty electric motor, heavy-duty spherical roller bearings, and reinforced shafts. It also features robust mechanical seals that inhibit abrasive dust and water penetration, and gear reducer to absorb heavy shock loads and high vibration. All GrizzlyDrive® components, including the electric motor, gear reducer, and bearings, are enclosed inside the drum and protected from the environment. VDG’s new premium-efficiency electric motor operates at low temperatures, increasing the lubrication viscosity of all components inside the drum, increasing reliability, and extending the service life of the new generation of GrizzlyDrive® Drum Motors. To ensure durability and longevity, VDG developed and patented an Oil Cooling-Conditioning unit for the GrizzlyDrive®. The VDG Oil Cooler-Conditioner circulates, filters, conditions, and cools the oil inside the drum in order to maintain optimal oil temperature and viscosity, averting motor failure and downtime, and the consequent costs. This unit is supplied as standard for GrizzlyDrive® Drum Motors 75 hp… Keep Reading

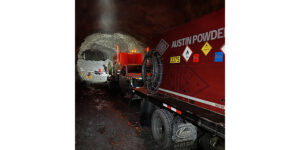

Austin Powder Company RED D MINER System

Austin Powder’s RED D MINER system is tailored to meet the diverse needs of underground quarries, construction, and mining operations. Its adaptability to varying prime movers and construction methods makes it one of the most versatile pump systems available. Designed for reliability in harsh conditions, it ensures long-term upkeep and ease of operation while maintaining affordability. With modular components and a user-friendly interface, the RED D MINER simplifies operations in environments such as room and pillar, stope and pillar, pillar removal, mine development, and underwater construction. Equipped with essential features like pump-specific safety systems and wireless remote control, it minimizes downtime and streamlines operations. Austin Powder continues to lead the industry in providing innovative solutions that cater to the evolving needs of our customers. See all the ways we can help your underground operation and watch videos describing how the RED D MINER helped our customers. Learn more Keep Reading

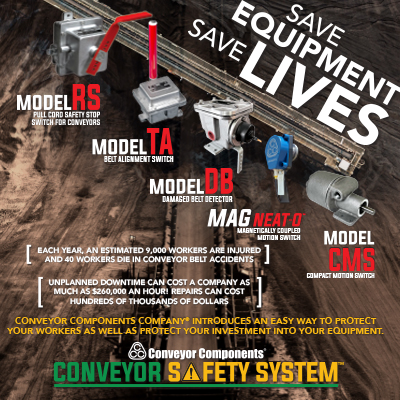

Conveyor Components Company: Conveyor Safety System

Conveyor Components Company® introduces an easy way to protect your workers as well as protect your investment into your equipment. The Conveyor Safety System™ is an easy, cost efficient way to get peace of mind and protection for conveyor equipment. By bundling our Model RS Safety Stop switch with our Model TA Belt alignment switch, Model DB damaged belt detector we have your workers and equipment covered. Couple that with adding one of our motion switches (Mag-Neat-O™ or Model CMS), you can feel confident knowing that your system and workers are protected... for a fraction of the cost of downtime, repairs and replacement equipment. You depend on your equipment, day in and day out. Repairs and downtime are becoming increasingly more expensive. The Conveyor Safety System is everything you need to make sure your conveyor is running safely and efficiently avoiding potential repair costs and safety hazards. Conveyor Components Company has been the most trusted name in conveyor safety equipment since 1965. Quality and Durability are our top priorities. Contact… Keep Reading