Author

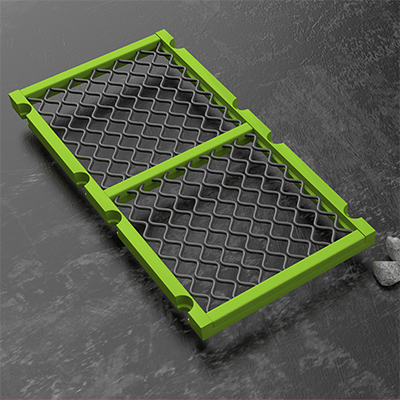

MAJOR FLEX-MAT Modular PLUS

MAJOR offers FLEX-MAT Modular PLUS, which is specially designed to withstand harsh screening conditions with the most abrasive materials, such as granite and basalt. The advanced screen media includes all the benefits of FLEX-MAT — high open area, efficient stratification, no blinding or pegging, and new and improved wear life comparable to polyurethane screen media. The PLUS series bonds OPTIMUMWIRE® — the industry’s longest-lasting wire — with distinctive lime-green polyurethane strips rather than weaving them. This allows wires to vibrate independently from end to end under material contact. The high frequency of the wires — 8,000 to 10,000 cycles per minute — adds to the vibration of the screen box — 800 to 900 cycles per minute — to speed up material separation and passing. The increased screening action improves material throughput while virtually eliminating pegging on the top decks and blinding and clogging on the bottom decks, resulting in a lower cost of production per ton. The media offers up to five times longer wear life than traditional woven… Keep Reading

CDE EvoWash

CDE have an exclusive offer to swap your sand screw technology for their EvoWash. CDE are so confident with the great output, product and profits this equipment can bring, that they will trade in your screw against a new EvoWash plus they are offering finance* to cover the balance. A compact, modular sand washing system, the EvoWash screens and separates the smaller sand and gravel fractions through an integrated high-frequency dewatering screen, sump and hydrocyclones which provide unrivaled control of silt cut points and eliminate the loss of quality fines with significant commercial value. Protecting revenue by eliminating the need for maintaining settling ponds, the EvoWash can integrate seamlessly into existing operations to reduce site footprint, minimize downtime and, with an increased number of parameters to ensure improved accuracy on the material cut point, remove the double-handling of materials, as high-value fines can often be lost and trapped at the bottom of ponds when processed with the more traditional sand screw. ENQUIRE TODAY. *subject to terms and conditions. Keep Reading

General Kinematics’ Mobile Aggregate Screening Plant

General Kinematics’ Mobile Aggregate Screening Plant is perfect for on-site screening operations. Featuring a mounted 6’ x 20’ GK Horizontal Screen, these mobile screens have superior material retention capabilities, meaning they can easily handle tough, abrasive, heavy, or wet materials that other screens may struggle with. Save time and money by screening aggregates right at the quarry. Just pull up, park, and get screening. Ready to optimize your aggregate screening process? Set up a meeting with GK’s aggregate experts to learn more! Keep Reading

HAZEMAG Primary Impactor (HPI) Series Primary Impact Crusher

HAZEMAG understands that the cement and aggregates industry has higher production demands, a need for cutting-edge technologies, and the demand for proven, reliable partners. That’s why they are proud to offer the HAZEMAG Primary Impactor (HPI) Series Primary Impact Crusher, which is ideally suited to crush medium-hard materials down to a product size of 0-8 inch in a single pass. The HPI Crusher utilizes the computer-controlled, fully hydraulic HAZtronic Apron Adjustment system to achieve high levels of both consistency and safety, boasting a high reduction ratio, reliable production at up to 2,800 t/h, and the latest CE-compliant safety features. HPI is a smart and reliable choice for your needs; visit https://na.hazemag.com/hpi/ today to learn more! Keep Reading

Portable Crushing & Screening Systems: Built Masaba Tough

Masaba’s wide range of material handling and processing products includes portable systems for crushing, screening, and washing, giving you the strength and versatility you need for your application. Our plants require minimal mobilization time; they are quick to deploy and easy to tear down. We proudly partner with the industry’s most trusted crusher and screen brands. Built MASABA Tough: Renowned for the most robust designs on the market, MASABA builds products that last, providing years of production and profits. Crushing Plants — Masaba builds the most rugged quad-axle plants for your pit and quarry needs, delivering efficient material processing. Screen Plants — Our screen applications are designed to maximize material sorting and output, increasing your bottom line. Wash Plants — Portable wash plants from Masaba combine the efficiency and productivity of our custom sand screws and washing components. Bins, Hoppers, Feeders — Simplify your material handling with Masaba hoppers, bins, and feeders — quality solutions for an endless flow of material. Custom Plants — Rely on our experienced engineers to… Keep Reading

Montabert Premium Heavy Breakers for the Toughest Applications

Montabert Premium Heavy Breakers are designed for all types of carriers, from 18 to 120 tons, and are ideal for a variety of applications, including quarrying, mining, excavation, and demolition. Features and benefits include: Automatic variable-speed technology senses changes in material hardness and adjusts impact energy and striking rate. This increases productivity, based on the application, and reduces blank firing. The technology also reduces unnecessary harmful energy from transferring to the carrier and breaker, helping to prevent wear on parts and components. Energy chamber acts as a hydraulic shock absorber and reduces pressure variations in the hydraulic circuits to provide consistent energy to the breaker — reducing pressure spikes and keeping the charge constant, with no periodic maintenance required. Progressive start system prevents slipping by creating a small recess in the material before full power is applied. Blank-fire protection system reduces damage on all wear parts by providing a cushion of oil that reduces the energy. Automatic lubrication system assures the breaker is constantly lubricated to improve life span on… Keep Reading

John Deere 350 P-Tier Excavators

Powerful productivity. Durable by design. P-Tier Excavators are built to make easy work out of your toughest tasks. Customer-inspired features include a robust front-joint, exceptional serviceability and cooler access, and options like camera arrays, and LED-surround lighting – for when the daylight fades before you do. Our machines deliver what you’ve come to expect in mid-size John Deere excavators, so you can stay focused on moving more rock day in and day out. Click the link below to see more on the 350 P-Tier Excavator, or check out current offers on this model and others at Deere.com/BigDeal. Learn more. Keep Reading

Superior Industries Brand-New Idler Design

Superior Industries just invested millions into a brand-new idler design and also upgraded manufacturing operations at the same time. The result is the most modern, longest lasting conveyor idler backed by the fastest manufacturing lead times in our industry. Learn more. Keep Reading

Dyno Nobel’s TITAN DIFFERENTIAL ENERGY

Dyno Nobel’s TITAN® DIFFERENTIAL ENERGY® Emulsion and Delta E2 (ΔE2) ® technology give operations the ability to place explosives energy exactly where it is needed in the borehole for optimized blasting. Using data from drills and other sources that characterize rock properties, explosives energy can be varied throughout the blasthole based on the specific geological conditions at blasting sites. The Delta E2 software allows blast plans to be sent directly to the loading equipment to ensure boreholes are loaded as designed, improving efficiency and accuracy by simplifying the loading process. By customizing the density of explosives based on rock characteristics using DIFFERENTIAL ENERGY and ΔE2, engineers and blasters have a finer level of control over fragmentation for increased production and reduced drill and blast costs. Visit dynonobel.com to learn more. Keep Reading