Author

Polydeck: METALDEX XPT

WIRE CLOTH THROUGHPUT. SYNTHETIC WEAR LIFE. EASY CHANGEOUTS. Stuck between fragile wire cloth and cast molded panels with not enough open area? METALDEX® XPT closes the gap. ✅ Abrasion-resistant welded wire, built for aggressive dry sizing✅ Lightweight 1' x 2' design—faster changeouts, fewer injuries✅ Polyurethane-encased for stability and safety during high-vibration screening✅ Up to 63.8% open area for high-volume sizing✅ Available in 30mm or 65mm thicknesses and "With Flow"/"Across Flow" formats Consider using METALDEX XPT if: 💥 Wire cloth can’t last, but cast molded panels hold you back. 💥 You have coarse sizing applications where durability AND open area matter. 💥 Changeouts are taking too long, and you don’t want to sacrifice the throughput wire cloth provides. Don’t settle for less tons or more changeouts. METALDEX® XPT meets you in the middle. Learn more Keep Reading

Elgin Separation Solutions: Tabor Reverse Incline Vibrating Screen

The Tabor Reverse Incline Vibrating Screen is a game-changer in the aggregate industry, delivering unmatched efficiency in sizing and dewatering applications. Designed with a unique reverse incline angle, this screen reduces blinding, increases material retention time, and maximizes separation accuracy. The result? Higher production rates, improved product quality, and reduced operating costs. Engineered for durability, the Tabor Reverse Incline is built to handle the toughest conditions while minimizing maintenance and downtime—keeping your operation running at peak performance. Whether you’re processing sand, gravel, or crushed stone, this screen ensures consistent results that keep your material flow moving. Ready to take your screening efficiency to the next level? Contact Elgin today and discover how the Tabor Reverse Incline Vibrating Screen can transform your aggregate operations. Learn more Keep Reading

ASGCO: Razor-Back CSB Series Secondary Belt Cleaners

The Razor-Back® CSB Series Secondary Belt Cleaners are engineered around a simple but powerful principle: continuous blade-to-belt contact with no gaps. Its innovative design ensures that the cleaning blade maintains consistent, even pressure across the entire belt width, eliminating the dead spots and uneven wear common in traditional cleaner systems. The result is uniform cleaning pressure from edge to edge, delivering superior carryback removal without compromising belt integrity. KEY FEATURES AND ENGINEERING HIGHLIGHTS Modular Blade Cartridge System High-Performance Materials Compact Footprint Wide Versatility Easy Retrofit and Integration Lower Maintenance Burden Extends Component Life Complies with Safety Regulations Belt widths from 18” to 96” Operating speeds up to 1000 FPM Applications in both wet and dry material flows Learn more Keep Reading

Eriez: Suspended Electromagnets

The Suspended Electromagnet provides tramp metal collection from conveyed materials. The electromagnet is typically mounted or suspended over a conveyor belt to remove large pieces of tramp metal that represent a hazard to downstream crushers, mills, pulverizers and grinders. Suspended electromagnets also remove sharp metal that can damage or tear expensive conveyor belts, especially at transfer points. Product purity is enhanced with the separation power of the suspended electromagnet. Learn more Keep Reading

Motion: Revolutionize Your Conveyor Belt Operations

Motion’s Durowall corrugated sidewalls are designed to revolutionize your conveyor belt operations. These sidewalls can take on your toughest jobs, ensuring that materials travel securely throughout your conveyance system. Whether you’re looking to implement these sidewalls in a new or existing system, the Motion Conveyance Solutions team is ready to help you today. Work with our Durowall sidewall sizing program to find the right combination of Durowall sidewalls, cleats and belting for your operations. Learn more Keep Reading

ME Elecmetal — Born in Mining. Built for Aggregate.

At ME Elecmetal, we don’t just supply wear parts — we engineer performance. With the same grit that built our mining legacy, we now lead the aggregate market in speed, quality, and custom solutions that help distributors outperform OEMs. What Makes Us Different? Velocity that Wins BusinessWe move faster than the OEM — from quote to delivery, we get your customers running quicker. Optimization Without the OEM HassleOur data-driven tools and expertise make it easier to tune performance and improve wear life — without the long waits or locked-in specs. Quality that LastsOur parts are engineered to outperform OEM standards — from metallurgy to manufacturing. Total Product Development PartnerWe don’t stop at crushing. We innovate in: Apron feeders flights Crusher Safety Tooling Rubber wear components Custom-engineered solutions Support that Doesn’t DisappearWe stand behind our products with global reach, responsive teams, and training that make you a hero to your customer. Diversified CapabilitiesFrom reverse engineering to flexible manufacturing, we create what the job demands — not just what the OEM offers.… Keep Reading

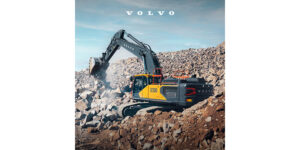

The New Volvo EC500 Excavator

Looking for an excavator that gives you a competitive edge? Here it is — the new Volvo EC500 excavator is a powerful evolution of one of Volvo’s most popular machines. Engineered for demanding tasks on mining sites and in quarries, it gets the job done safely and efficiently. Need some numbers? Get up to 15% improved fuel efficiency and up to 10% faster cycles, contributing to a lower total cost of ownership and higher profit margins. The upgraded, modern cab provides a more spacious and comfortable environment with intuitive controls, ensuring operators can take on the long days with ease. Coupled with enhanced safety features and easier maintenance, the Volvo EC500 is designed to meet the diverse needs of both owners and operators, so you can take on more jobs and achieve unparalleled productivity. Ready to get a leg up on the other guys? Find Your Edge Keep Reading

Elevate Your Fleet with Premium Bucket Trucks

Don't miss the opportunity to upgrade your aerial equipment in Purple Wave's September 11th construction auction. Don’t miss the 5 late-model Freightliner business class bucket trucks, perfect for utility work, tree trimming, or any job that requires reaching new heights. But that's not all – our auction boasts a generous variety of bucket trucks from different makes and models, ensuring you'll find the perfect fit for your specific needs. Whether you're looking for a compact unit for urban work or a heavy-duty truck for challenging terrains, we've got you covered.And for those seeking to expand their construction capabilities, we're also offering an impressive selection of dozers, wheel loaders, and other essential equipment.Visit purplewave.com today to explore our full inventory and place your bids. Remember, it's a no-reserve auction – every item will sell to the highest bidder. Don't let this chance slip away! Keep Reading

Smiley Monroe ToughFlex Conveyor Belts: Built for the Hardest Hits

Designed for extreme conveying environments, Smiley Monroe’s ToughFlex® conveyor belts combine outstanding impact resistance with long-lasting durability. Built with a unique 2-ply construction and additional binder warp, ToughFlex® offers excellent troughability and doesn’t compromise on strength. It’s the perfect fit for high-impact applications like construction, demolition, and crushing. Lasting up to four times longer than standard EP Multiply belts ToughFlex® is designed to handle aggressive materials, high drop heights, and challenging transfer points. With multiple spec and supply options including cut length, endless and Zip Clip®, ToughFlex® is precision-built for your machine and your load. ToughFlex® belts are also available flat or with chevron customisation. Trusted by leading OEMs and already powering performance in road construction, C&D recycling, and mobile crushing worldwide, ToughFlex® is the go-to belt for high-impact performance. Find out more about ToughFlex conveyor belts Keep Reading