Author

NSSGA: Thank you to all of our 2024 Partners!

NSSGA recognizes those who support us by partnering to sponsor our programs and events. The support of our partners makes possible our ability to hold and deliver effective events for our members. We thank these steadfast supporters of our association. Learn more Keep Reading

C&D Recycling 101: How To Recycle Aggregate Materials and Work Toward Zero Waste

Photo: McLanahan C&D recycling allows producers to process material more responsibly and sustainably. Whether you are just starting out in C&D recycling or you are an aggregate producer with an existing processing plant who wants to add recycled aggregate to your product offering, download this ebook to learn more about C&D waste materials and the best practices for recycling C&D debris. Learn more. Keep Reading

ZIP CLIP replacement belts are slashing machine downtime

[Sponsored Content] Supplied ready-to-fit, with premium dispatch options available, mechanically fastened ZIP CLIP® replacement belts can be safely installed in just one hour - and run immediately. Keep Reading

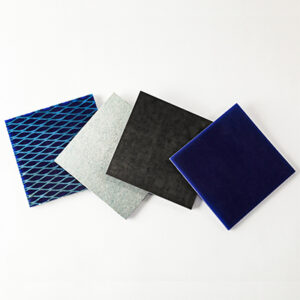

Haver & Boecker Niagara: Rhino Hyde Liners

Photo: Haver & Boecker Niagara Haver & Boecker Niagara offers Rhino Hyde liners to enhance the wear life of a full range of equipment. The company’s custom-blend liners are strategically formulated and installed on key wear, material handling and impact areas of chutes, hoppers, vibrating screens and more. Rhino Hyde, constructed from thermoset polyurethane, boasts superior abrasion resistance, durability and chemical resistance compared to alternatives like thermoplastic polyurethane, rubber or metal. Rhino Hyde liners are formulated and proven to outperform rubber, plastics and even metals in rough weather. Producers can enjoy more durability with reduced wear in high-abrasion or high-impact areas. Additionally, Rhino Hyde liners offer a simple fix to seal worn spots. Polyurethane liners are a cost-effective solution and have the unique characteristic of being higher wear but are also a lighter-weight product with reduced maintenance and replacement costs. Rhino Hyde liners are designed for applications such as screening, material handling and hauling. They can be fully customized to the required size and are available in multiple different styles… Keep Reading

Deister inclined screens deliver super-duty efficiency & performance

Photo: Deister Deister BHM Series Triple-Shaft Inclined Screens provide a super-duty separating & sizing solution that delivers accurate, dependable, and efficient performance – even in the most demanding applications. Deister triple-shaft screens feature three individually motor-driven shafts, which optimize material movement and separation, while preventing clogging. Ideal for use where headroom is limited – the BHM Series combines mechanical simplicity with maximum capacity – as its triple-shaft vibrating mechanism is placed between the decks. Offering rugged, super-duty construction, the Deister BHM Series is built for minimal maintenance and reduced operating costs. Its quantity-controlled oil lubrication ensures long bearing life, while its unitized vibrating mechanism provides precision performance in adverse operating conditions. Interchangeable screen panels and tension plates allow customization for specific applications. No matter the sizing, material type, or capacity requirements, Deister customizes every screen to meet exact customer specifications. Contact Deister today to find your super-duty solution to lower costs per ton. Learn more. Keep Reading

Astec Industries Vari-Frequency Screen Technology

Introducing the latest in Astec screening technology. This new technology promises to revolutionize the industry with its novel approach to screen cloth blinding reduction. This patent-pending innovation offers increased performance and reduced operating costs. • Uses standard, side-tensioned screen wire cloth• Functionality is achieved through a deck that generates multiple vibrations throughout the length of the screen• Self-cleaning technology eliminates the need for manual cleaning• Does not require an external power source• Screen has common interface points with other low-profile screens for easy replacement Learn more about how this new technology can help you keep the stickiest of screening jobs on track. Keep Reading

Know Your Options: Circular Motion Incline Vibrating Screen

Photo: Conn-Weld Conn-Weld specializes in custom engineering and fabrication, their equipment is designed and manufactured to fit your exact specifications. Conn-Weld’s Circular Motion Incline Vibrating Screens are available with a multitude of special features and options. Offering many deck frame designs, a variety of media configurations, and several mechanism sizes, Conn-Weld’s Incline Screens support numerous applications. Product Features and Options: Customizable Deck Clearances A Variety of Screen Media Mechanish with Spherical Roller Bearing External Counterweights Field-Proven Steel Coil Springs Trunion Mounted or Fixed-Bracket Designs Heavy-Duty Deck Support Frames Sight Glass Viewing Oil Level Jacking Pads for Spring Maintenance Spring Guards Manifold Spray System Dust Cover H-Beam Base Wedge-Base A Variety of Wear Protection:CeramicUrethaneSteel Rubber Learn more about more about your options: Circular Motion Incline Screen Animation - Conn-Weld Keep Reading

Luff Industries: Quality Conveyor Components

Photo: Luff Industries Celebrating its 45th Anniversary in 2024, Luff continues to supply high-quality, long-lasting conveyor components all over the world. Luff products are manufactured to withstand the harshest applications and can be used with confidence in medium to heavy duty operations. From idlers to pulleys, to impact beds and accessories, all of Luff’s products must pass through a rigorous ISO 9001 quality inspection program and are backed by a full two-year warranty. For more information on increasing your conveying performance with Luff products, please contact us today! Learn more. Keep Reading

Trux Material Delivery Logistics

Photo: Trux Make material delivery logistics a competitive advantage with increased throughput, improved dispatching and plant efficiency, and unparalleled customer service with complete delivery tracking and transparency. Trux delivers significant enterprise value to your organization with tools for dispatching haulers and tracking haulers, monitoring material delivery progress, optimizing plant efficiency, E-ticketing, and customer engagement. How much value can you expect when you use Trux? We’ve created a simple value calculator to help you determine the incremental dollar value YOU can expect to add to your business with Trux. Learn more. Keep Reading