Author

HAZEMAG CYBAS-i Cone Crusher

Photo: Hazemag Unlock unparalleled productivity with the HAZEMAG CYBAS-i Cone Crusher. Its spherical spider bearing not only delivers a higher pivot point for optimal eccentric motion but also ensures better chamber utilization, leading to reduced downtime and lower operating costs. This innovative feature maximizes throughput while minimizing maintenance expenses, making it a cost-efficient choice for your crushing needs. The CYBAS-i crusher is equipped with material-specific insert (MSI) liners that create a unique grooved crushing chamber. This design harnesses three powerful forces—compressive, bending, and shear—to produce a more cubical product shape while consuming less power and minimizing fines generation. Furthermore, the curved crushing chamber design significantly reduces flat and elongated (F&E) product issues, ensuring a consistent and desirable shape. Whether you're looking to boost productivity or achieve higher product quality, the CYBAS-i is the ideal solution. 👉Ready to elevate your production? Visit our website or call 724-439-3512 to request a quote today! Keep Reading

Stay ahead of the curve with this powerful motor grader

Photo: Komatsu With standout horsepower and best-in-class blade downforce pressure, the GD955-7 achieves honor-roll status for its ability to efficiently build and maintain quarry haul roads for truck fleets of 100 tons and up. Designed to cover more ground faster and effectively penetrate hard-packed haul road surfaces, be sure to make the cut with this star performer. Learn more about making the grade with Komatsu’s GD955-7 motor grader. Keep Reading

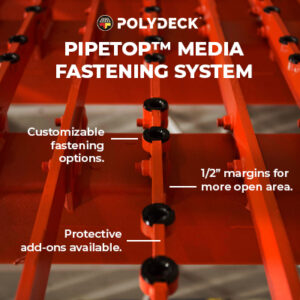

Polydeck PIPETOP SYSTEM

Photo: Polydeck The POLYDECK PIPETOP SYSTEM is an OEM agnostic media fastening system designed with versatility and open area in mind. With custom sizing, wear-protection add-ons, and multiple fastening styles, the PIPETOP SYSTEM is designed to fully leverage the potential of our products and bring best-in-class open area and wear life to your screens. FEATURES Configured to fit your preferred OEM deck size requirements. ½” wide stringer rails for maximum throughput. Independent fastening ferrule inserts for individual replacement as need arises. PROTECTIVE ADD-ONS PROTEX RC (Rubber Lining) PROTEX UC (Urethane Coating) PROTEX PTP (Molded Polyurethane Stringer Protectors) Multiple fastening options and stringer configurations available. Learn more about our PIPETOP Media Fastening System today. Keep Reading

InnoDredge: Dredging Solutions

Photo: InnoDredge InnoDredge, formerly ROHR-IDRECO Americas, specializes in innovative dredging solutions, offering a range of advanced dredges including electric suction, clamshell, and bucket ladder models. With a commitment to sustainability, innovation, and client focus, InnoDredge serves North, Central, and South American markets, providing durable, efficient equipment for various dredging applications such as sand, gravel, wet mining, and underwater stone. The company prides itself on delivering top-tier performance and reliability, supported by extensive parts and service options. For more details, visit InnoDredge. Keep Reading

GIW LCC pump

Photo: KSB GIW, Inc. The GIW® LCC pump is the most reliable pump for the toughest duties in aggregate production. The LCC can handle anything from solids-laden waste to the most abrasive slurry. LCC’s rugged design features hard wearing components constructed of proprietary Gasite® white iron or natural rubber which are recognized worldwide for superior abrasion resistance. Options are included for operating without flush water. The LCC pump delivers on 3 key features: high efficiency, low maintenance and the absolute lowest total cost of ownership. The Quick Ship Program delivers pumps in 2 weeks, and spares in 1 week. Contact GIW to learn more. Keep Reading

Protect Crushers & Screeners from Costly Damage

Photo: Eriez ERIEZ metal detectors stop damaging metal fragments traveling on conveyors before they reach downstream crushers and screeners. ERIEZ MetalArm metal detector’s technology identifies the foreign metal for removal, while limiting disruptive “false trips.” Eriez metal detectors are designed around the conveyor belt for easy installation. Learn more. Keep Reading

Luff Industries: Belt Brush Cleaners

Photo: Luff Industries Luff’s Belt Brush Cleaning Unit is available in a variety of sizes to accommodate any belt cleaning application needed. Driven by its own electric motor, the brush turns opposite to the direction of the belt travel, delivering a positive cleaning action. A take-up style rod assembly provides simple brush adjustment and hanger brackets mount directly on the conveyor frame for easy installation. Standard brush comes with nylon bristles, rubber bristle brush is available. Rubber bristles provide a sweeping action to remove materials and are best used on cleated, chevron or ribbed belts. The flexible bristles can provide more aggressive brushing action compared to nylon, without causing excessive wear. Contact us today for more information on Luff’s Belt Brush Cleaners. Keep Reading

Superior Industries: Urathon Return Roll

Photo: Superior Industries When it comes to durability, polyurethane reigns supreme. Compared to traditional conveyor idler materials like steel or rubber, polyurethane, exhibited in Superior's Urathon Return Roll, not only outlasts and outperforms but sets a new standard altogether.In similar aggregate handling scenarios, polyurethane trumps rubber by lasting at least three times longer and leaves steel in the dust with its unmatched performance. Imagine the savings on maintenance costs once you factor in this longevity.What sets Superior's polyurethane apart is that it's crafted in-house. This ensures shorter lead times, meticulous quality control, and an unparalleled understanding of chemistry, which you simply can't achieve with outsourced production. Learn more. Keep Reading

L&H Industrial’s Tramp-Release System Helps Operators Avoid Downtime

Photo: L&H Industrial L&H Industrial's tramp-release system is designed to ensure safety, dependability and ease of installation. As a high-value asset in the processing operation, L&H says a tramp event or a related issue directly impacts safety, productivity, maintenance and the overall operation. According to L&H, its system removes stored energy by replacing conventional mechanical springs. It also releases pressure on cylinders and allows the adjustment to pick up, repressurizing cylinders to return to the optimal crushing position. The tramp-release system can be retrofitted onto legacy crushing equipment for upgrades in safety and production, the company says. Also, the system can increase production levels by allowing a crusher to run at maximum feeds without the fear of a tramp event. Read Free Case Study Now Keep Reading