Author

Superior Industries: Sentry Horizontal Shaft Impactor (HSI) Crusher

Photo: Superior Industries The Sentry® Horizontal Shaft Impactor (HSI) Crusher from Superior Industries is a versatile solution for material recycling and aggregate processing. Engineered for robustness and reliability, it excels in demolition, aggregate recycling, and road base production. The crusher handles diverse materials with fewer fines compared to Vertical Shaft Impactors (VSI), ideal for concrete, asphalt, glass, and brick recycling.Key features include a spacious chamber for feed sizes up to 40-inches, a high-powered rotor for maximum crushing force, and user-friendly hydraulic functions for easy maintenance. Universal side liners extend wear life and reduce costs. Its rugged design is suitable for various applications, including clay, brick, quarried stone, and recycled asphalt. The crusher includes inspection doors, replaceable upper feed openings, and robust blow bars.The Sentry HSI is perfect for portable plants, offering flexibility with a third curtain or grinding path. Backed by a 2-year/6,000-hour warranty and dedicated support, it ensures reliable performance and customer satisfaction, making it a valuable investment for sustainable material recycling and efficient processing. Learn more. Keep Reading

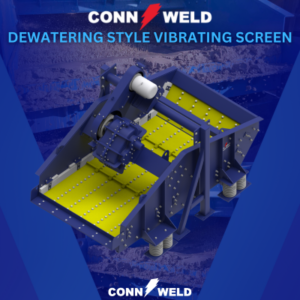

Conn-Weld High-Frequency Dewatering Screen

Photo: Conn-Weld Conn-Weld’s High-Frequency Dewatering Screens are designed to handle one of the toughest challenges in screening- dewatering. Conn-Weld Dewatering Screens are engineered to create a thick bed depth that traps fine particles and allows water to drain more effectively. When combined with Conn-Weld’s G-Master Drive Mechanism, you have a premium performance, high-speed screen that can tackle your toughest dewatering duties. Features & Options: Customized for above ground or underground installation High speed performance with minimum maintenance G-Master Drive Mechanism with spherical roller bearings Reinforced Side Plates Heavy Duty Support Frame Ceramic and Urethane Lining Pivoting Motor Base Wide variety of screen surface Learn more. Keep Reading

Unified Screening & Crushing: Ask Unified

Photo: Unified Screening & Crushing Consistency is critical. You want the NEXT set of wear parts to last as long as the last set. Unified manganese quality begins at the foundry: *Unified products are inspected four to five times during the actual manufacturing process. *Everything from the heating of the material, to the pouring temperatures, even the cooling, and then the quenching process are closely monitored. #AskUnified. Learn more. Info@unifiedscreening.com 800-332-6463 Keep Reading

General Kinematics’ Portable Horizontal Screen

Photo: General Kinematics General Kinematics’ Portable Horizontal Screen is perfect for on-site screening operations. Featuring a mounted 6’ x 20’ GK Horizontal Screen, these portable screens have superior material retention capabilities, meaning they can easily handle tough, abrasive, heavy, or wet materials that other screens may struggle with. Save time and money by screening aggregates right at the quarry. Just pull up, park, and get screening.Ready to optimize your aggregate screening process? Learn more about GK’s Portable Horizontal Screen! Keep Reading

Everything you Need to Operate Smarter, Safer, and More Sustainably

Photo: Xylem The water-related challenges facing the mining industry are complex, but Xylem's Mining Solutions Center has everything you need to turn mine water management into a strategic advantage. Explore Xylem's trusted solutions and learn how our extensive portfolio, smart technologies and superior field service capabilities can help you minimize water waste and downtime. Learn more. Keep Reading

ASGCO: Safe-Guard Conveyor Belt Lifter

The Safe-Guard® Conveyor Belt Lifter is a patent pending tool developed to make lifting a tensioned conveyor belt easier. Conveyor maintenance is made safer and effortless with the ease and mobility of the lifter allowing for the lifting of all belt troughs, including flat belts. Easy to use. The Safe-Guard® Conveyor Belt Lifter can be easily operated with a manual ratchet or drill. Works on a wide range of conveyors. The Belt Lifter is for belt widths 36”-60” (900-1500 mm). Belt can either be lifted flat or in troughed position. Safe. Features an extendable study dual-rail base and high lift capacities. Easy operation. Its compact and lightweight design ensures easy-to-use operation. Won’t damage the belt. Lift the belt from underneath. Does not clamp onto the belt’s edges or cover. Need solutions to improve Efficiency, Safety & Productivity? ASK ASGCO. Learn more Keep Reading

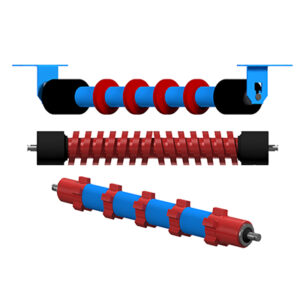

Luff Industries: Urethane Return Rollers

Photo: Luff Industries Luff Industries has introduced a variety of urethane products to its product lines, including several return roller options. The Urethane Return Rollers offer efficient cleaning, belt friendly designs that outlast and outperform rubber return rollers up to 5 times. Clean Weave spiral design cleans the bottom side of the conveyor belt through an augering action. The roll discs are always contacting the belt in a new area increasing the cleaning action. The Urethane Beater Return Roller effectively cleans the belt and is engineered to be safe for cleated belts. For more information about Luff’s Urethane Return Rollers please contact us today! Keep Reading

Canica, a Terex Brand – “We Know Crushers!”

Photo: Canica, a Terex Brand Canica® offers a comprehensive range of Static, Modular and Portable Vertical Shaft Impactors (VSI) to customers around the world. Our VSI’s are designed to produce highly cubical end products in small sizes, while eliminating soft material. A properly configured Canica VSI Crusher is the key to minimizing wear costs and downtime, while maximizing profitability. We offer one of the widest ranges of configurations on the market with open shoe table, enclosed rotor and rock shelf, rotor and rock box combinations. Which means, no matter your production or operational need, there is a Canica VSI solution able to manage the load. Our VSI crushers are known for their robust construction geared toward the professional aggregate producer. As a legacy brand of Terex MPS, we are dedicated to ensuring the best products on the market and we back that with our trusted service and parts for the life of your equipment. Find out more about our Canica VSI crushers and locate an authorized distributor near you to… Keep Reading

Dings Company: Simpler is Better.

Photo: Dings Co. Magnetic Group If tramp metal is rare in your process but must be removed… Sometimes Simpler is Better. Dings Overhead Stationary Electromagnets protect your conveyors, crushers, screens and other valuable processing equipment from damage caused by tramp metal. The stationary model, with no moving parts, is virtually maintenance-free. All you need to do is periodically check the cooling oil. The stationary model has no self-cleaning belt to sag, allowing for a lower suspension height and making the use of a smaller, more economical magnet possible. The feature that makes Dings electromagnets the best choice for your application is our unique coil design of anodized aluminum strap instead of insulated wires. This coil design produces a stronger, deeper and more uniform magnetic field than the others and doesn’t require an external oil tank or pipes. Dings Company stands behind the quality of their electromagnetic coil design with an industry best 20-year warranty on coil burnout. Contact us to discuss your application and metal separation needs. Keep Reading