Author

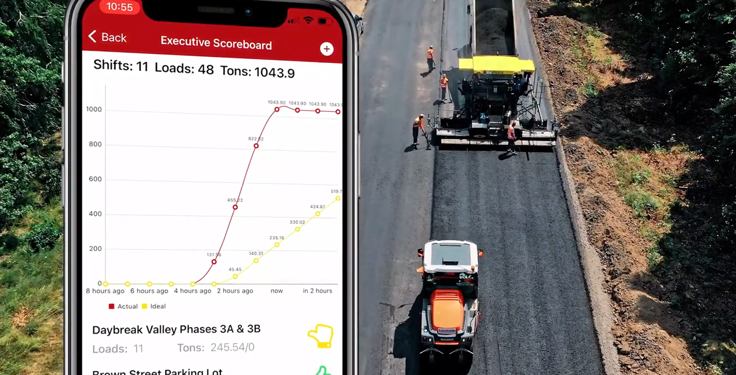

Do you have access to real-time jobsite data?

[SPONSORED CONTENT] FleetWatcher’s Construction Management and Materials Management Solutions allow contractors to track materials at quarries, plants, and job sites. Keep Reading

HAZEMAG’s HCS Center Sizer

Photo: Hazemag Unleash the power of efficiency with HAZEMAG’s HCS Center Sizer! Designed to tackle even the toughest materials like clay, coal, and limestone, this compact powerhouse offers high throughput with superb control over product size, all while keeping fines to a minimum. With its energy-efficient operation and low maintenance demands, the HCS Center Sizer is your go-to solution for cutting costs and enhancing performance. Upgrade your material processing today with HAZEMAG and experience innovation that drives results! Learn more about the HCS Center Sizer and request a brochure here. Keep Reading

Amcast: Crusher Wear Parts and Mining Solutions

Photo: Amcast AMCAST is an industry leader for premium crusher wear parts and mining solutions capable of handling the most challenging crushing applications. AMCAST consistently invests in technologies and manufacturing processes to solve impact and abrasion problems through hi-tech steel alloys, Wear Resistant Inserts (WRI), and a variety of heat treatments suitable for any crushing application. Our objective has always been to empower our customers with the tools and knowledge necessary to take their crushing operations to the next level. Come see us at West Hall Booth 11473 at MINExpo 2024, or learn more at amcastonline.com. Keep Reading

FleetWatcher Small Tools and Attachment Tracking

FleetWatcher's small tool and attachment tracking lets you know where your small assets are by job and class of asset. Using bluetooth technology and the FleetWatcher user app, you can manage all of your small tools and attachments. Our durable asset tags can be added to a variety of tools and attachments including buckets, trench boxes, equipment attachments, saws and more. You and your crew will always know where your assets are on the jobsite. Visit our site. Do you have access to real-time jobsite data? Tune into our video to learn more. Keep Reading

BKT USA Earthmax SR 49

Photo: BKT USA, Inc. The EARTHMAX SR 49 is an all-steel radial tire that has been engineered for loaders and dozers, low profile dump trucks (LPDT) and load haul dumps (LHD). The EARTHMAX SR 49 provides optimum performance in severe mining operations requiring exceptional traction and stability. The tire has a directional pattern and is made of a special cut-resistant compound providing excellent durability. This tire is available in various sizes including our most popular seller, the 35/65R33. About BKT For over 30 years, BKT has led the way in the creation and manufacture of safe, innovative, and performance-focused tires for a range of specialist sectors, including the construction, earthmoving, port, mining, and agricultural industries. To learn more, visit our website at https://www.bkt-tires.com/ww/us/. Keep Reading

Shell Tellus S3 V 46

Photo: Shell Shell Tellus S3 V 46 is a zinc-free hydraulic oil designed especially for excavators and haul trucks that require zinc-free oil. It also provides excellent protection and performance in a wide range of hydraulic systems, including stationary equipment like crushers and mill drives. Shell Tellus S3 V 46 helps avoid servo valve failures caused by varnish that can result from lower quality oils. Because of its outstanding temperature performance, Shell Tellus S3 V 46 can be used year-round, winter and summer. With excellent filterability, it is an ideal choice for use in systems where filtration is deployed to remove quarry contaminants. Shell Tellus S3 V 46 can be used in high pressure, high temperature and heavily loaded systems. Learn more. Keep Reading

Unified Screening & Crushing: Screen Replacements

Photo: Unified Screening & Crushing Material fatigue is real. Abrasion is the primary reason for wear in crushing applications. Screens play an important role in reducing the chance for fines to recycle in your feed. Don’t wait to replace a worn or, worse, broken screen. With 14 locations across the country, Unified Screening & Crushing can replace your screens WHEN you need them. * And don’t forget – rails, channel rubber, bolts and fasteners – you can source it all with Unified. Info@unifiedscreening.com 800-332-6463 Learn more. Keep Reading

McLanahan: Ultra Fines Recovery Systems

Photo: McLanahan Ultra Fines Recovery Systems provide the finest size fraction recovery available without the use of chemicals. When using a UFR, the recovered material is conveyable and stackable and is suitable for multiple industries, including sand, industrial sands, frac sand and more. Recovering fine solids can produce a standalone product, reduce solids reporting to the settling ponds and reduce the solids loading on downstream processing. Recovered fines can help producers save money, create an additional saleable product, reduce fines reporting to the pond or be used for property rehabilitation. McLanahan | Ultra Fines Recovery Plants Keep Reading

Martin: Idlers

Discover the ultimate solution for your challenging belt conveyor applications with Martin's proven high-performance idlers. Engineered to exceed CEMA standards, Martin Idlers feature robust construction and an industry-leading seal system, ensuring durability and long life even in the harshest conditions. Martin stocks steel, impact, and disc return idlers, as well as impact beds and return guarding, ready to ship the same day. Each product is designed for optimal performance, minimizing downtime and maximizing material throughput. Equip your operations with the best—choose Martin Idlers & Pulleys for reliable, long-lasting performance. Request a quote today! Keep Reading