Author

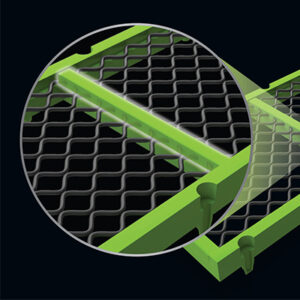

MAJOR Improves Screen Media Durability with New Advanced Polyurethane Strip Variant

Photo: MAJOR MAJOR introduces an advanced polyurethane (PU) strip variant for the FLEX-MAT Modular series. The new variant increases the screen media’s durability, extending its lifespan and effectiveness in alkaline, acidic and wet environments by offering greater chemical stability. Advanced durability extends the overall wear life of screen media in applications like limestone operations where the PU strips typically wear out before the steel wire and affect the integrity of the screen media. The unique chemical compound we developed for our advanced PU strips hold up well against corrosive materials to ensure the strips match the lifespan of our OPTIMUMWIRE® and maintain screening integrity up to 10 times longer. The high frequency of OPTIMUMWIRE remains — 8,000 to 10,000 cycles per minute — to speed up material separation and passing. Like MAJOR’s standard polyurethane composition, the advanced PU strips are available for the FLEX-MAT Modular D, S and T Series. The new variant is not intended to completely replace the standard polyurethane. To learn more about advanced PU strips, FLEX-MAT… Keep Reading

Douglas / Rulmeca: Premium Conveyor Components

Photo: Douglas / Rulmeca At Douglas / Rulmeca, we are leaders in the design and manufacturing of premium conveyor components that power industries around the globe. With a shared passion for innovation and quality, we are committed to delivering solutions that enhance conveyor safety, boost operational efficiency, and drive profitability for our customers. Our mission is to engineer the highest-performance conveyor components in the market while offering the fastest lead times in the industry.Our lineup of conveyor pulleys, including drum and self-cleaning wing styles, is designed to withstand the toughest environments. Whether you need Heavy Duty, Mine Duty, Quarry Duty, or Engineered Class pulleys, we have the perfect solution for your most demanding applications.Douglas / Rulmeca also specializes in premium conveyor idlers, built for the rigorous requirements of CEMA B, C, D, E, and F+ applications. With durable welded steel frames and a variety of configurations—such as troughing, return, impact, and self-aligning—our idlers provide enhanced stability, superior sealing, and extended service life.We pride ourselves on our fast lead times, high-quality… Keep Reading

Luff Industries 45th Anniversary

Photo: Luff Industries Celebrating its 45th Anniversary in 2024, Luff continues to supply high-quality, long-lasting conveyor components all over the world. Luff products are manufactured to withstand the harshest applications and can be used with confidence in medium to heavy duty operations. From idlers to pulleys, to impact beds and accessories, all of Luff’s products must pass through a rigorous ISO 9001 quality inspection program and are backed by a full two-year warranty. For more information on increasing your conveying performance with Luff products, please contact us today! Learn more. Keep Reading

BKT USA EARTHMAX SR 50

Photo: BKT USA, Inc. The EARTHMAX SR 50 (L-5) is an all-steel radial tire specially designed for loaders. The durable casing and sidewall protectors are ideal for the most demanding operations. The EARTHMAX SR 50 is made of a special cut-resistant compound which ensures a long wear life. Operators will also appreciate its excellent traction, stability and comfortable ride. This tire is available in sizes 26.5R25 and 29.5R25. About BKT For over 30 years, BKT has led the way in the creation and manufacture of safe, innovative, and performance-focused tires for a range of specialist sectors, including the construction, earthmoving, port, mining, and agricultural industries. Learn more. Keep Reading

Do More with New Volvo Excavators

Photo: Volvo It’s true, all excavators move material — Volvo’s new models just move more. And while some excavators can save you a little cash, redesigned Volvo excavators rewrite the rules on efficiency, saving you more time, more fuel and more money. Add it all up, and that means you can spend a little less time on site, and more well-deserved time out doing what you love. Redesigned Volvo excavators — get your edge and do more with your day. Explore the models now > Keep Reading

Dings Overhead Stationary Electromagnet

Photo: Dings Company If Tramp Metal is Rare in Your Process but Must be Removed… Sometimes Simpler is Better. Dings Overhead Electromagnets produce a deep, uniform magnetic field that removes ferrous tramp metal before it can cause damage to your conveyor belts, crushers, screens, and other processing equipment. With no moving parts Dings Stationary Electromagnets are virtually maintenance-free. No belt assembly or belt sag allows for a reduced suspension height, making the use of a smaller, more economical magnet a possibility. Dings unique electromagnetic coil design delivers the best performance on the market and comes with an industry best 20-Year Warranty on coil burnout. Our coil design also eliminates the need for installation of an expansion tank for cooling oil. All the cooling oil needed is contained in the magnet box itself. We build our magnetic separators to meet your application’s specific needs. Contact us to discuss your application and metal separation needs. Keep Reading

Shell Rotella ELC HD

Photo: Shell Shell Rotella ELC HD (Extended Life Coolant Heavy Duty) is a high-performance, heavy-duty engine coolant that is designed to provide long-lasting protection for diesel engines. Some of the benefits of Shell Rotella ELC HD include: Extended service life: Shell Rotella ELC HD is designed to provide extended service life of up to 15,000 hours of operation, depending on the application. This can help to reduce maintenance costs and downtime. Excellent protection: Shell Rotella ELC HD provides excellent protection against corrosion, cavitation, and scale formation, helping to extend the life of the engine and its components. Reduced maintenance: The extended service life of Shell Rotella ELC HD means that maintenance intervals can be extended, reducing the need for frequent coolant changes and associated maintenance costs. Compatibility: Shell Rotella ELC HD is compatible with a wide range of materials commonly used in engine cooling systems, including aluminum, brass, copper, and steel. Overall, Shell Rotella ELC HD is an excellent choice for heavy-duty diesel engines, providing extended service life, excellent protection,… Keep Reading

AMCAST: Crusher Wear Parts and Mining Solutions

AMCAST is an industry leader for premium crusher wear parts and mining solutions capable of handling the most challenging crushing applications. AMCAST consistently invests in technologies and manufacturing processes to solve impact and abrasion problems through hi-tech steel alloys, Wear Resistant Inserts (WRI), and a variety of heat treatments suitable for any crushing application. Our objective has always been to empower our customers with the tools and knowledge necessary to take their crushing operations to the next level. Learn more Keep Reading

Mettler Toledo: TruckPass

Photo: Mettler Toledo For sites experiencing bottlenecks with fleet traffic at the truck scale, TruckPass is the solution. Keep traffic and revenue flowing with TruckPass: the first and only legal-for-trade weigh-in-motion system for full-length truck scales. When matched with an automated ID system, trucks will no longer need to stop on the scale to complete a time-consuming registration process, saving your operation time and money. Call 1- 800-METTLER or visit TruckPass Weigh-in-Motion (mt.com) to learn more. Keep Reading