Author

Luff Industries: Impact Beds

Photo: Luff Industries Impact beds help to absorb impact and support the full width of the conveyor belt. It’s designed to eliminate spillage and belt damage, dramatically improve efficiency and reduce maintenance costs. Luff impact bars have a UHMW surface along with a polyurethane base specifically engineered to absorb and disperse the force of impact. Luff’s impact frame design allows for the impact bars to be easily replaced without removing the skirting by simply removing the bolts and sliding the section of frame out, reducing downtime and maintenance costs. Custom and low-profile designs are available to suit your needs. Contact Luff today for more information on how to increase your Conveying Performance. Learn more. Keep Reading

Regal Rexnord – Your Cement Facility, Our Solutions

Photo: Regal Rexnord Discover how Regal Rexnord’s offerings can help keep your toughest cement applications up and running. Our products are engineered to meet cost and performance criteria, ensuring you have an efficient solution - while also prioritizing safety. Rugged solutions from Regal Rexnord are found in conveyors, crushers, shaker screens, bucket elevators, industrial fan / cooling systems, and many other applications. Learn more. Keep Reading

Shell Rotella T6 Engine Oils

Photo: Shell Heavy-duty diesel engines operate under extreme conditions in quarries, including high loads, high temperatures, and exposure to dust and other contaminants. The oil used in these engines must be able to withstand these conditions and provide reliable protection against wear. If you’ve experienced turbo-charger coking issues from the use of lower-quality oils, switch to Shell Rotella T6, the most advanced engine oil in the Shell Rotella portfolio. Shell Rotella T6 is specifically designed for use in heavy-duty diesel engines, making it an ideal choice for use in the harsh operating environments of quarries. Its advanced synthetic formulation provides exceptional wear protection, helping to extend the life of engines and reduce maintenance costs. Additionally, its resistance to deposit formation helps to ensure reliable performance over extended periods of use, even in the hottest of ambient conditions. Shell Rotella T6 is a fully synthetic engine oil that exceeds common industry requirements, such as CK-4, ECF-3, JASO DH-2 and more. Shell Rotella T6 is available in multiple viscosity grades. Learn more. Keep Reading

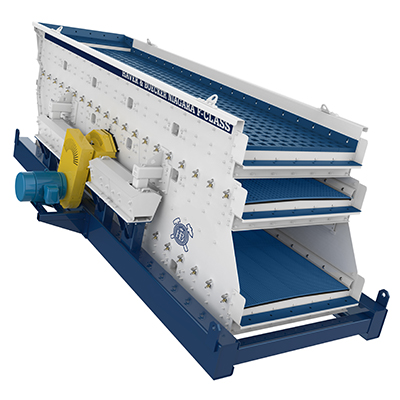

Haver & Boecker Niagara Next-Generation Niagara F-Class Vibrating Screen

Photo: Haver & Boecker Niagara Haver & Boecker Niagara’s Niagara F-Class vibrating screen features new technology for simplified maintenance combined with maximum performance and longevity. The updated design retains the technical benefits the original F-Class is known for, such as improving performance in material stratification and reducing blinding and pegging. The vibrating screen is primarily manufactured with vibration-resistant lockbolts instead of traditional welding. Lockbolts are more effective at maintaining structural integrity during operation while making vibrating screen maintenance more convenient, safer and cost-effective. Additionally, Haver & Boecker Niagara redesigned the flat deck models of the new F-Class to create the largest amount of open area possible for modular screen media. Featuring replaceable polyurethane anchors, the new high open area modular deck is suitable for virtually any pin and sleeve modular screen media. The F-Class can be manufactured for side-tensioned or bottom deck end-tensioned screen media. Each new side-tensioned machine comes with Haver & Boecker Niagara’s signature Ty-Rail™ quick-tensioning system with the ability to cut screen change-out times in half. The… Keep Reading

Smart Pumping Has Never Been Easier With the Addition of Xylem’s Flygt Pareo

Photo: Xylem As a monitoring and control system that drives automation and connectivity for any traditional dewatering pump in your mine, the Flygt Pareo enables up to 70% less wear-and-tear on the pumping system, reducing equipment life cycle costs and improving the reliability and safety of pumping operations. Learn more. Keep Reading

General Kinematics: Horizontal Aggregate Screens

Photo: General Kinematics General Kinematics Horizontal Aggregate Screens are engineered for superior material retention. They can easily handle tough, abrasive, heavy, and wet materials, making them ideal for challenging applications that require greater precision. Custom-built for your screening needs, these horizontal screeners fit seamlessly into your facility's existing footprint. Increase your screening efficiency with GK’s Horizontal Screen! Keep Reading

VDG (Van der Graaf): New Premium-Efficiency GrizzlyDrive Drum Motors

Photo: VDG The GrizzlyDrive® Drum Motor is maintenance-free for 80,000 hours of continuous operation and withstands the harshest of environments where performance, reliability, and durability matter most. All components, including the new premium-efficiency electric motor, gear reducer, and bearings, are enclosed inside the drum and protected from the environment. The electric motor operates at low temperatures, increasing the lubrication viscosity of all components inside the drum, increasing reliability and the service life of the new generation of GrizzlyDrive® Drum Motors. Available up to 500 hp, with a wide range of diameters, belt speeds, lagging, and options to suit various belt conveyor applications. Find out more. Keep Reading

HAZEMAG: HAZtronic System

Photo: HAZEMAG Introducing the HAZtronic System: an innovative, computer-controlled hydraulic adjustment feature designed specifically for the impact aprons and third crushing path of HAZEMAG impact crushers. This state-of-the-art system enables rapid gap adjustments, ensuring precise control over product size, smoother operation, effective tramp iron protection, minimized downtime, and lower operating costs. With the HAZtronic system, you can optimize impactor performance using customizable recipes or pre-programmed apron settings, which elevate the quality and consistency of your output. Experience unparalleled performance and cost efficiency with HAZEMAG’s premium solution. Upgrade your crushing operations today—embrace the power of HAZtronic! Visit our website or call 724-439-3512 to request a quote today! Keep Reading

Buffalo Wire Works Exclusive Offer: Save 7% On All Bulk Orders Placed By January 10th, 2025!

Photo: Buffalo Wire Works Exclusive Offer: Save 7% On All Bulk Orders Placed By January 10th, 2025! Gear up for the 2025 season with our special 7% discount on screening media and wear parts! This limited-time opportunity helps you avoid last-minute rushes and ensures your product is ready to perform at its best throughout the season. Contact the Buffalo team by phone or email and mention promo code BULK2025 to take advantage of this exclusive offer! Learn more. Keep Reading