Author

TerraSource Global: Jeffrey Rader NFE Electromechanical Vibrating Feeder

TerraSource Global’s Jeffrey Rader® feeders are designed to maximize operations with enhanced structure for handling large, lumpy materials more efficiently with reduced energy consumption. Our latest innovation, the NFE Electromechanical Vibrating Feeder, offers enhanced efficiency and safety with its pure balanced linear motion and near-zero maintenance design. Featuring precision tuning and rugged construction, these feeders excel in handling various materials, from crushed stone to industrial substances, ensuring reduced energy consumption, simplified maintenance, and superior safety standards. Contact a TerraSource Global representative today to learn about our full line feeding solutions. Learn more Keep Reading

Deister combines super-duty screens with cost-saving technologies

Deister super-duty screens deliver rock-solid, reliable production day after day – even under the most adverse operating conditions. Visit Deister at AGG1 2025 booth #3931 and get the latest information on how Deister combines super-duty vibrating equipment with innovative cost-saving technologies. Save time, money, and oil For operating cost savings, the Deister System Saver can be added to your Deister screen. Without exposing oil to the open environment, the System Saver filters out harmful contaminants in the lubricating oil, allowing reuse of the oil. Importantly, it extends the life of the antifriction bearings in the lubrication system, while reducing costly bearing replacement, system downtime, and oil disposal costs. Eliminate costly downtime from clogged nozzles & pipes The patented Deister Spray Water Strainer easily collects and discharges the accumulated solids from the wash screen water system, while providing strained water to multiple wash screens in the circuit. The result is greater wash plant uptime, optimum water flow and sprayer performance, and maximum water velocity and cleaning action to the screen. American-Made… Keep Reading

Keep Trucks Moving With the SURVIVOR OTR-IMS

Rice Lake Weighing Systems is a global leader in weighing and measurement solutions, offering durable, long-lasting truck scales. Rice Lake now offers the SURVIVOR® OTR-IMS in-motion truck scale system, an innovative solution for increasing productivity and site safety. The SURVIVOR OTR-IMS cuts emissions by shortening truck idle time and eliminating lines of trucks waiting to be weighed. This in-motion truck scale system can also reduce maintenance by limiting truck braking and improve site safety by allowing drivers to complete transactions from their cabs. SURVIVOR OTR-IMS Features • Patent pending system • Single-draft weighing • Legal for Trade weights • Industry-leading support The SURVIVOR OTR-IMS system consists of the 1280 Enterprise™ Series weight indicator with Legal for Trade, in-motion software. It is paired with the LaserLight3™ remote display, a speed sensor and a SURVIVOR OTR truck scale. Compatible with steel or concrete deck SURVIVOR OTR truck scales, the SURVIVOR OTR-IMS system can be installed with new scales or retrofitted to existing scales, enabling every facility to boost productivity and revenue with in-motion… Keep Reading

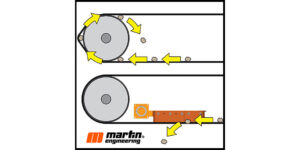

Martin Engineering: Torsion VPlow Plus

Martin Engineering® recommends protecting the tail pulley for greater efficiency and improved workplace safety. Pulley fouling happens when spillage on the return side of the belt travels to the tail pulley, is crushed by the pressure between the belt and the pulley, and then adheres to the pulley face and the belting. A fouled tail pulley causes slippage and abrasive damage on the unprotected side of the belting. Friction heat from a fouled pulley warps and weakens the belt and becomes a fire hazard. A Martin® Torsion VPlow Plus deflects debris away from the tail pulley, protecting it. Mounted with a self-adjusting suspension, it reacts to fluctuations in the belt profile. Improve workplace safety and avoid expensive equipment damage by installing a Torsion V-Plow. Visit www.martin-eng.com for more info. Learn more Keep Reading

Luff Industries: North American Standard Roller

The North American Standard Roller (NAS) was developed to allow its customers to standardize on one, high quality roller, to decrease operating and maintenance costs and increase efficiency. The advantages of standardization are numerous, but most importantly it decreases costs, saves time, increases output and provides consistency. The ability to save time and simultaneously increase output produces a more efficiently run conveyor system. Standardization also provides consistency in the product and quality of that product, so the customer knows exactly what to expect in terms of longevity and performance. This concept was at the core of developing the NAS Roller. Each roller is manufactured to Luff’s high-quality standards but can fit into a variety of different manufacturer frames. The NAS Roller is currently available in 5” CEMA C Steel Trough Rolls, for 24” – 48” belt widths, for 12 different idler manufacturers. Customers can now purchase one roller, the NAS Roller, for all their conveyors, regardless of the original manufacturer. Please contact us for more information on the North American… Keep Reading

Belt-Way Conveyor Belt Scales

Reduce your black belt time by improving efficiency with Belt-Way Scale’s in-motion weighing solutions. Whether you are building out a new facility or adding conveyors to an existing plant, Belt-Way’s scales, integrators, and monitoring tools are easy to install and calibrate, the fastest installation time in the industry. Our equipment’s easy-to-use design and rugged durability help you maximize output and efficiency at your plant for a quick ROI. Belt-Way’s Plant Connect and the valuable data it provides can help you make black belt a thing of the past. Plant Connect monitors your production in real time, lets you take charge of your inventory with custom reports, and analyzes your data to improve performance and reduce downtime. The Plant Connect mobile app for Android® and Apple® is free with Plant Connect activation and puts real-time monitoring in the palm of your hand 24/7. Belt-Way customer service doesn’t end with the sale. In fact, that’s where it starts. Belt-Way’s nationwide network of over 300 authorized equipment dealers make it easy to receive assistance,… Keep Reading

Eriez: Magnetic Separation and Metal Detection Equipment

Magnetic separation and metal detection equipment from Eriez protects downstream equipment and preserves product purity by eliminating damaging metal contamination. Stray metal like digger teeth and tools can not only damage expensive crushers and screeners; the revenue losses due to downtime can be exponential. Suspended electromagnets from Eriez continuously and automatically remove damaging tramp metal from conveyed materials. Available in a wide range of sizes and configurations, these electromagnets ensure your operation runs at top efficiency every day. Pairing a suspended electromagnet with an industrial metal detector ensures that any nonferrous metals do not damage downstream equipment. With class-leading reliability and sensitivities, metal detectors from Eriez are easy to install and protect your plant and process. Learn more Keep Reading

BKT USA EARTHMAX SR 41

The EARTHMAX SR 41 is an all-steel radial tire perfect for articulated dump trucks, loaders, and dozers. Thanks to its all-steel structure and special block pattern, the EARTHMAX SR 41 provides excellent resistance against punctures and an extended service life. In addition to long working hours without downtime, the tire ensures extraordinary comfort. The EARTHMAX SR 41 is also available in SH4**** for Low Profile Dump Trucks (LPDT) used in underground haulage operations. About BKT For over 30 years, BKT has led the way in the creation and manufacture of safe, innovative, and performance-focused tires for the Off-Highway tire industry, that includes a range of specialist sectors, such as agriculture, construction, earthmoving, port and mining. Our pioneering technology and dedication to continuous improvement has made us the partner of choice for those operating in some of the most challenging environments on the planet. With distribution partners in over 160 countries on five continents, we are proud to serve a truly global customer base. Learn more Keep Reading

Heico Fastening Systems: Prevent Bolt Loosening and Ensure Safer Torque Tightening with Reaction and Safety Washers

The next step forward in wedge locking washer bolt security technology is here! Tighten large bolts without the risk of using a high torque tool reaction arm. HEICO-LOCK® Reaction Washers combine the superior locking function of our Wedge Lock Washers with the SPEED and SAFETY of reactionless torque tightening. For through-bolts, the new HEICO-ONE Safety Washer acts as a backup washer, ensuring accurate torque tightening. Learn more Keep Reading