Author

ABB Motors and Mechanical Baldor-Reliance motors

Dusty, dirty, wet, outdoor, and potentially high vibration environments require motors up to the task - those with enough starting and peak torque for the job as well as the ability to handle overloads. ABB’s Baldor-Reliance® crusher duty motors offer the flexibility, reliability, and performance tough conditions demand. Learn more at this link. Keep Reading

ESR Motor Systems

ESR Motor Systems supplies electric motors, VFDs, soft starters, and gearboxes to quarries throughout the United States. Being a distributor for every major motor manufacturer, we offer the Aggregate Industry’s most accepted brands. Our extensive inventory is tailored to our quarry customers’ needs and includes quarry duty, severe duty, and Vertical Hollow Shaft motors as well as heavy-duty soft starter and VFD packages. Contact one of our industry experts today at 1-800-868-3770 or visit us at www.esrmotors.com Keep Reading

Regal Beloit Perceptiv 24/7 monitoring

You need to keep your pumps running. Unplanned downtime can be your worst enemy, costing you time and thousands of dollars. With the help of the Perceptiv™ 24/7 monitoring solution, you can guard critical production assets from unpredictability. Get instant web-based notifications of problems such as pump failure, power outages, phase loss and rising water to provide predictive warnings, so you can quickly learn about and address issues before there is downtime. With the help of the Perceptiv monitoring solution, you get insight into the future and can keep production going. For more information, click here. Keep Reading

Allied Construction Products Compactor Drivers

Allied Construction Products pioneered the concept of a boom-mounted vibratory compactor/driver with the invention of the Ho-Pac® in 1965. Today’s Ho-Pac line is comprised of many models designed to be mounted on a variety of carriers including mini-excavators, rubber-tired backhoes, excavators and even trenchers with a backhoe attachment. Our Skid-Pac® models mount on a skid steer, and use the same technology as the Ho-Pac line. Both compactor/drivers save time and money, and increase job productivity by expanding the versatility of equipment and eliminating the need for special purpose machines. https://www.alliedcp.com/product-category/compactor-drivers/ Keep Reading

Haver & Boecker Niagara offers Ty-Rail tension rail system

The Ty-Rail™ quick-tensioning system from Haver & Boecker Niagara solves an age-old problem of time intensive screen media change-outs. Replacing tension rails is typically time consuming and requires removing and replacing many pieces of hardware per screen section. Washers or bolts are often dropped or lost in the process, which adds to downtime and parts costs. The Ty-Rail system provides a fast return on investment, and cuts screen change-out time in half by simplifying the process. The system is designed specifically for Haver & Boecker Niagara’s brand of side-tensioned vibrating screens and includes two tension rails, eight angle boxes and eight bolts. Keep Reading

Luff Industries Line Idlers

Luff Industries’ top of the line idlers are built with a patented endcap design that offers the ultimate in strength, durability and sealing performance. Keep Reading

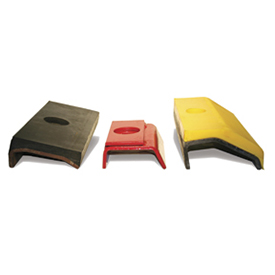

Unified Screening & Crushing

Make change outs easier! Unified Screening & Crushing stocks screen rails in rubber, steel, and urethane. Want to able to pull everything from the same pallet? Count on Unified for ALL your screen installation needs = rails, channel rubber, bolts and fasteners. Single sourcing means less work for you, and greater efficiency for your front line team. www.unifiedscreening.com Keep Reading

AZFAB quad attrition mills

AZFAB QUAD Attrition Mills were designed to scrub sand particles against one another in order to liberate ultra fine materials. Keep Reading

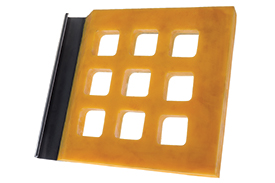

Ty-Max Hooked Screen Media from Haver & Boecker Niagara Maximizes Longevity While Reducing Pegging

Ty-Max screen media from Haver & Boecker Niagara maximizes uptime on challenging wet and dry screening applications. Ty-Max is poured using open cast technology and permanently hardens when cured to maintain its chemical properties, so it resists wear and tear. The polyurethane also wears exponentially longer and handles direct feed better than wire cloth, maximizing productivity by reducing change-outs. Additionally, Ty-Max features an internal wire grid as thick as 3/8 inch to reinforce the screen. Ty-Max is hooked for a cambered deck to eliminate the need for a deck conversion, making it ideal and cost-effective for both the aggregates and mining industries. Keep Reading