Author

Precision Pulley & Idler conveyor cover

Protecting your belt as well as your bulk materials is important in the conveying industry. PPI offers a solution in both full and three-quarter conveyor covers to protect your application. Standard in galvanized steel, you can count on PPI Conveyor Covers to be strong and hold up to a multitude of environmental challenges. https://www.ppi-global.com/product/conveyor-cover/ Keep Reading

McLanahan Sand Classifying Tanks

Widely-used in sand, gravel, and crushed stone plants, McLanahan Sand Classifying Tanks provide an efficient and simple way to remove excess water and slimes or undesirable grain sizes from sand feeds. With decades of engineering and manufacturing Classifying Tanks and the components of Classifying Tank Based Sand Plants, McLanahan's expertise is unmatched. Whether you need to remove excess amounts of water from your feed or produce multiple products from a single feed, McLanahan can design a Classifying Tank Based Sand Plant for your specific application. More information Keep Reading

Sturtevant Mobile Whirlwind Air Classifier

The Whirlwind Mobile Air Classifier removes excess fines from aggregate products bringing materials formerly considered waste materials into specification. Keep Reading

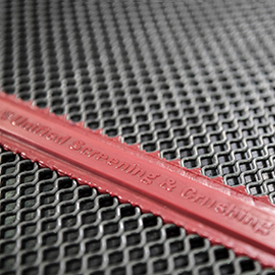

Unified Screening & Crushing

Material fatigue is real. Abrasion is the primary reason for wear in crushing applications. Screens play an important role in reducing the chance for fines to recycle in your feed. Don’t wait to replace a worn or, worse, broken screen. With 14 locations across the country, Unified Screening & Crushing can replace your screens when you need them. And don’t forget – rails, channel rubber, bolts and fasteners – you can source it all with Unified. Email: Info@unifiedscreening.com Phone: 800-332-6463 www.unifiedscreening.com Keep Reading

Haver & Boecker Ty-Wire Hybrid Screen Media

Ty-Wire screen media from Haver & Boecker Niagara offers a highly efficient screening alternative to traditional screen media. Featuring a unique design that delivers as much as 80% more open area than modular polyurethane, Ty-Wire minimizes blinding and virtually eliminates pegging to increase screening efficiency and operational uptime. The unique hybrid design also reduces maintenance costs and enhances product longevity, especially in aggregates applications. Made with high-carbon woven wire encased with engineered polyurethane composite, Ty-Wire withstands high temperatures and tonnages, and is guaranteed to last at least four times longer than wire cloth. Ty-Wire is available in both modular panels and hooked sections. About Haver & Boecker Niagara Haver & Boecker Niagara is a leading provider in screening, pelletizing and mineral processing plants and systems. The company’s mission is to deliver the best of these technologies to customers in the mining, minerals, aggregates, cement, building products, fertilizer and salt industries. With deep roots and years of experience in these industries, Haver & Boecker Niagara uses its innovative and shared technologies… Keep Reading

Three ways to make the most of your gearbox purchase

In 2019, capital expenditures (CapEx) — or funds used to acquire, improve or maintain a company’s physical assets — for top mining companies grew by over 10 percent, reaching $49.billion. While gearbox spend can be about 3-5 percent of the cost of a typical mining application, they can often be the linchpin of the operation. Gearbox failure is not an option when keeping production running. To ensure your company will get a good return on investment (ROI) and turn those expenses into profit, follow these critical steps on the pre-commissioning, commissioning and post-commissioning of the machine set. 1. Use precision installation techniques with documentation The Operating and Maintenance manual typically provided by the manufacturer gives the proper procedures for startup, operation and even long-term storage. Scott Arnett, National Aftermarket Operations Manager, says, "one of the most common forms of failure we see with gearboxes relates to misalignment, whether on the input or output side." Misalignment can lead to preloaded bearings and seal failures and will severely reduce the life of… Keep Reading

Regal Beloit Seal Master Time Saving bearing

The multiple award-winning Sealmaster Time Saving bearing features a patented axial groove in the inner ring bore at setscrew locations. This feature allows for easier bearing removal by eliminating interference with the burr and ability to reuse the shafting with minimal cleanup. Available for ball bearings at shaft sizes 2 7/16” and up, and for ALL available sizes of USRB (unitized spherical roller) bearings, the Time Saving bearing saves you more than just time! Learn more Keep Reading

Watch the Vermeer T1255III Terrain Leveler SEM at work

On the northeast coast of Malta, the Polidano Group is excavating rock at Sliema with a Vermeer T1255 Terrain Leveler, a challenging project in the old town. Learn more. Keep Reading

8 questions to ask yourself before replacing a gearbox

The time has come. This specific gearbox has possibly been around before you started working at your facility. It's frequently having issues like mechanical failures and needs more maintenance than your team has time to complete. The CAD drawings might be missing, or the manufacturer is no longer in business to replace the gearbox or components if you wanted to. If this situation sounds like yours, it may be time to replace your gearbox. Before you do, ask yourself these eight questions and read the Gearbox Replacement Planning Guide from Sumitomo Drive Technologies before replacing your gearbox. 1. Are you happy with the performance and life cycle of your gearbox? Technology has changed drastically in the last 20 years. Gearing and gearbox components are no different. Efficiencies in gearing and motor performance have improved, seals and seal materials are better, synthetic lubrication can extend life dramatically, and condition monitoring can keep you from shutting down unexpectedly. Would you take your 20-year-old Ford or Chevy to the dealer and ask them… Keep Reading