Author

Hazemag Sizer

The Hazemag Sizer is designed for the processing of soft to medium-hard raw materials. It is an excellent solution when the raw material contains cohesive materials (clay) with a high moisture content. The operating principle is based on a continuous generation of pressure between two counter – rotating rolls, so that crushing takes place without interruption. Sizer Features: low specific energy demand high to very high throughput rate intelligent design simple maintenance high variety of crushing tools cubicle product with minimal fines trouble – free operation with very sticky and moist materials applicable for adhesive feed material NA.Hazemag.com Keep Reading

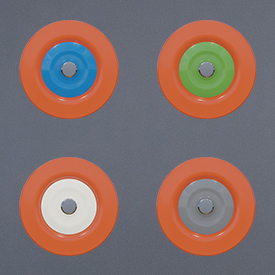

Superior Industries Application-Specific Conveyor Idler Seals

These next-generation SpinGuard® Idler Seals will offer greater protection in applications known to expose bearings to fugitive material prematurely. Keep Reading

Smiley Monroe Zip Clip

With an easy-to-fit push-in connecting pin, Zip Clip is a fast, safe and secure installation method developed specifically for Aftermarket spares. Keep Reading

Smarter water management in mining

At Xylem, we find ways to integrate technology to increase productivity, reduce costs and turn water management from an expense to a strategic advantage. Keep Reading

Surestrike International mechanical breakers

Surestrike mechanical breakers are the simple, low cost and dependable solution for breaking materials such as oversize rock. Keep Reading

Choosing the right gearbox for the right application

We talk a lot about gearbox startup, asset management and extending the life of your investment, but what about making sure you have the right industrial gearbox for the job? It may seem trivial, especially if you are on the MRO side, as you often have to trust that the equipment builder made the right decision when designing. However, what might seem practical or economical on the OEM side may not always translate to the MRO side. This tends to be a concern when it comes to standard shaft mounted units, where belts, sheaves and pulleys are commonplace. In these applications, which most often involve conveying equipment, general-purpose shaft mounted units provide an economical solution. However, it’s important to also factor in safety and ease of use. Before replacing your next shaft mount, consider these essential points. Equipment protection Belts offer a built-in failure point, which protect your equipment from sudden shock loads that can occur in many conveying applications. Many gearbox options provide better than average service factors. Cycloidal… Keep Reading

Cedarapids CRC1150S closed circuit cone and screen plant

The Cedarapids CRC1150S delivers high capacity in a portable closed circuit plant that combines the 300 hp TC1150 cone crusher with the highly efficient 6x20 3 deck TSV screen. This cone utilizes high efficiency roller bearings and boasts several notable advancements that enhance performance and functionality including automated cone controls, large feed opening and wide range of closed side settings. The screen, known for its efficient, high g-force El-Jay® oval stroke motion, handles heavy deck loads and features more steel in the “rock zone” for industry leading durability. www.terexmps.com Keep Reading

ABB Motors and Mechanical Dodge Torque-Arm II belt guard

Designed to protect workers from rotating equipment, ABB’s new Dodge Torque-Arm II belt guard has been enhanced with features that increase safety and reduce operating costs. Maintenance crews can now easily inspect v-belts mounted in the most common mounting positions, while following MSHA/OSHA regulations. Other benefits of the new belt guard include a sliding motor slot cover, which enhances safety while accommodating multiple motor sizes, side panels to eliminate unsafe access to rotating parts, lifting provisions to assist with safe installation and an easy access panel for trouble-free maintenance. Learn more. Keep Reading

Luff Industries conveyor systems

Luff Industries Ltd. has been increasing the performance of conveyor systems for over 40 years. Recognized for innovative products, quick turnaround times and exceptional customer service, Luff conveyor components can be found in a variety of industrial material-handling applications around the world. Manufacturing a complete line of idlers for every application, industry-leading pulleys, impact beds and many other products, Luff Industries provides the most complete line of conveyor components in the industry. All products must pass through an ISO 9001 quality inspection program and are backed by a full two-year warranty. Contact Luff today to increase your Conveying Performance. Keep Reading