The Model CT, manufactured by Conveyor Components Co., is comprised of a control unit and tilt probe that senses the presence or absence of material. The control unit is enclosed in a rugged cast aluminum housing with external red and green LED status indicator lights and surface-mount printed circuit boards. Weatherproof, dust-ignition-proof and explosion-proof models are available. According to the company, the Model CT is commonly used when other controls won’t work due to bin vibration or when bin walls aren’t available for mounting other controls. Typical applications include level detection in hoppers, silos, stackers, crushers and conveyor transfer points.

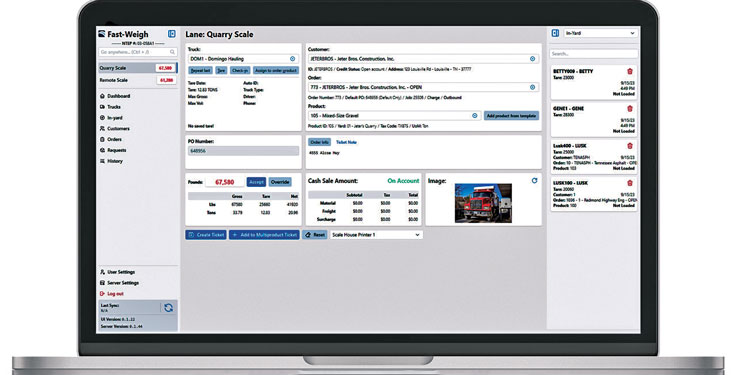

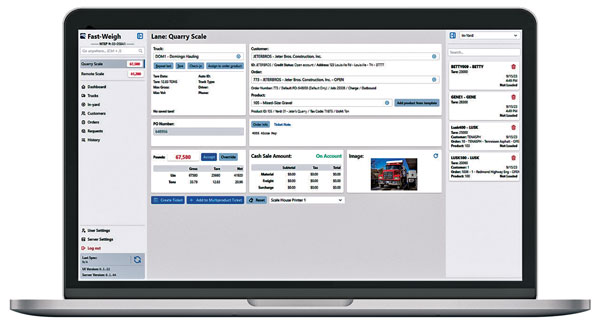

Next-gen scale ticketing software surfaces

The next generation of Fast-Weigh scale ticketing software offers greater scalability and the ability to handle “super sites” with multiple scales and users more efficiently. According to TAC Insight, its latest software features a single-gateway PC installation that’s capable of supporting unlimited no-install ticketing clients. As the company describes, other improvements to its software are a new, more intuitive user interface; an improvement in cloud sync speeds; new remote ticketing features; direct payment and credit card processing; enhanced security and performance; and improved search function.

Excavating tool made for rugged conditions

The 9.5-cu.-yd. extreme-duty bucket from Werk-Brau features an aggressive dig angle that easily faces off shale, rock, limestone, slate and other overburden. According to Werk-Brau, the 17,500-pound bucket is designed for abrasive environments and includes 2.5-in. side cutters, lower and upper vertical shrouds, a triple-layer internal liner, inner-side wear plates, double-external bottom and wear strips, heel shrouds, and Esco Nemisys N655 series teeth.