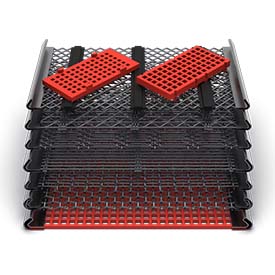

Major will showcase Flex-Mat modular screen media at AGG1 (Booth 2116).

According to Major, Flex-Mat is its signature screen media that delivers increased throughput by providing more open area than traditional panels. Flex-Mat features up to 40 percent more screen capacity than traditional woven wire, the company says, and up to 50 percent more than traditional polyurethane and rubber panels.

The product’s high-frequency movement makes media an active part of the screening process, Major adds, offering improvements in efficiency.

“Quality is key to any operation, which is why we place a strong emphasis on it at Major,” says Bernard Betts, president of Major. “We understand that no two operations are identical, which is why we configure each screening panel to precisely fit individualized requirements. That attention to detail is how we achieve what alternative media cannot: unrivaled throughput and superior end product quality.”

The modular panels are available in three pattern options: the D, S and T series. The D series features a standard square pattern, which is ideal for precise sizing. The S series maximizes open area, virtually eliminates blinding and reduces fine contamination, according to Major. The T series enhances screening for particles below 0.059 in. and features small openings to minimize blinding. The screen media is secured through either grooved, step or pin and leg panels.

Flex-Mat panels are available in either OptimumWire or 304 stainless steel wire. In addition to modular panels, Major’s Flex-Mat media is available in tensioned sections for use on crown decks.