Caterpillar introduced eight next-generation skid-steer loader and compact track loader models. Four new skid-steer loaders – the Cat 250, 260, 270 and 270 XE – mark the introduction of the next-generation design to the skid-steer line, according to Cat. Meanwhile, the new Cat 275, 275 XE, 285 and 285 XE mark the expansion of the next-generation design for the compact track loader line, joining the 255 and 265 that were unveiled last year. The Cat 285 and 285 XE are the largest compact track loaders Caterpillar has ever produced. They compete in a new class size, featuring greater lift height and lift and tilt breakout forces.

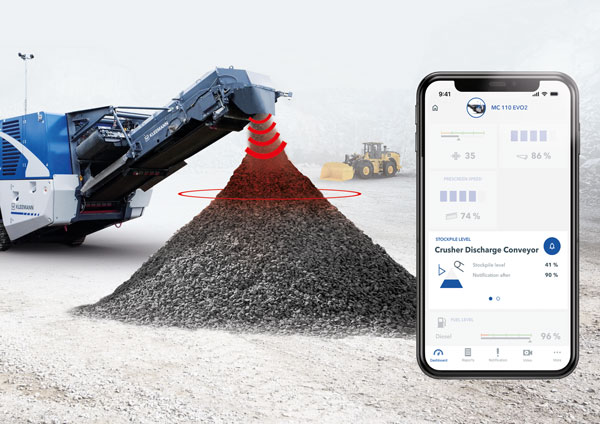

Stockpile monitoring function now part of mobile app

Kleemann added a stockpile monitoring function to Spective Connect, the company’s mobile application supporting operators on the job. According to Kleemann, the new function allows Spective Connect users to display the status of material stockpiles at all times. Users can dictate when they want to be informed about a stockpile’s height. Spective Connect now sends operators push notifications so they can clear full material stockpiles at the appropriate time. The company says stockpile monitoring is helpful on extensive terrain and with larger plant trains.

New emulsion addresses dynamic water

BME, a blasting and explosives company, developed Innovex 300D, a high-strength bulk emulsion explosive for surface mining conditions that include dynamic water. According to Rakhi Pathak, BME’s global manager of strategic partnerships, dynamic water is a common issue for surface mines leading to a variety of operational and environmental challenges. Pathak says these conditions exacerbate operational difficulties and environmental hazards. To counter these challenges, BME says Innovex 300D offers enhanced resistance to dynamic water, reducing the likelihood of misfires. BME says the product features an adjustable rheology, making it suitable for highly friable and fractured geological conditions.

Shock-resistant electronic detonators enhance safety

Dyno Nobel expanded its electronic detonator line with the DigiShot XR series, which is designed with extreme shock resistance. The new series includes three detonators: DigiShot XR, DigiShot Plus XR and DigiShot Plus XRS. According to Dyno Nobel, the new detonators improve on the industry’s current offerings with tailored technologies built to perform in extreme conditions. In high-dynamic shock environments where detonator failure is possible, Dyno Nobel says DigiShot XR, DigiShot Plus XR and DigiShot Plus XRS offer shock and EMP resistance through designed stress relief, precise component placement and material selection.

Two rigid-frame models join haul truck lineup

Komatsu introduced its new HD465-10 and HD605-10 mechanical haul trucks to North America, offering an upgrade from the previous -8 models. The HD465-10 is a 60-ton rigid-frame machine with a high-payload capacity and efficient hauling capabilities. The HD605-10 mechanical haul truck is a 70-ton rigid-frame machine designed for reliability and durability. The company says the new haul trucks are designed to help increase productivity and improve fuel efficiency in mining and aggregate applications.

Screening app updated to streamline, enhance productivity

Major combined two of its apps into one resource for aggregate producers and equipment dealers. The app update combines the Major app with the Flex-Mat sensor app. Depending on the user, Major says the new app includes marketing materials, expert documents and a newsroom with articles and announcements, as well as the RFID reader technology and the Flex-Mat sensor. Customers and dealers can now track and store screen media data such as screen dimensions and customer-defined details to simplify the ordering process through Flex-Mat ID Enabled. The RFID technology allows customers and dealers to access product information through the app without an additional reading device.

Object-detection system now on manufacturer’s production-class loaders

John Deere expanded its portfolio of jobsite safety solutions and technology offerings with SmartDetect for select utility-class and production-class loaders. SmartDetect technology utilizes cameras, radar and machine learning tools to enhance overall situational awareness and provide visibility to an operator’s surroundings. Prioritizing operator visibility, perception and awareness, SmartDetect combines cameras and machine learning to give operators a better view of their surroundings. SmartDetect utilizes the machine’s integrated digital cameras and a dedicated rearview high-resolution monitor to supplement an operator’s jobsite visibility. John Deere says the stereo camera on the rear of the machine enables depth perception to identify and classify known objects, further improving awareness.

Related: Safety hazards to watch for during seasonal maintenance