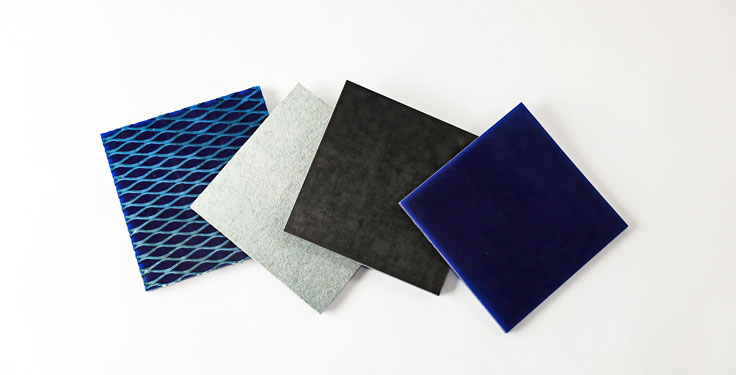

Haver & Boecker Niagara’s custom-blend Rhino Hyde liners are formulated and installed on wear, material handling and impact areas of chutes, hoppers and vibrating screens. Rhino Hyde, which is constructed from thermoset polyurethane, offers abrasion resistance, durability and chemical resistance, the company says. Rhino Hyde liners offer a simple fix to seal worn spots, according to Haver & Boecker Niagara. The liners can be fully customized to the required size, and they’re available in different styles and attachment systems such as the Rhino Hyde Blue, magnetic, urethane-backed ceramic, polyurethane blades, belt skirting and weldable liners.

Parts to extend equipment life, minimize changeouts

Unified Screening & Crushing has more than 6,000 tons of wear parts in its inventory to choose from. With more than 10,000 patterns available, Unified says customization offers end users equipment featuring a longer wear life and requiring fewer changeouts. According to the company, its wear parts meet OEM specifications and can be engineered to meet unique applications to crush highly abrasive material, handle oversize material, reduce recirculation, increase wear life and lower operating costs.

Wear solutions for crushing applications

ME Elecmetal provides wear solutions tailored for crusher operators across the mining, aggregate and recycling sectors. With solutions for primary, secondary and tertiary crushing applications, ME Elecmetal says it offers alloys that ensure unparalleled durability and performance. The company prioritizes safety, durability and usability in its offerings, and its comprehensive range of crusher safety tooling is designed to enhance operational efficiency and ensure tasks are completed safer, faster and smarter.

Liners to withstand impact, abrasion at transfer points

Dura-Tuff urethane canoe liners from ASGCO are engineered to absorb impact and abrasion in all types of material transfer operations. Made from an ASGCO-exclusive urethane compound with a durometer of 80/85, along with steel backing plate for added support, Dura-Tuff urethane canoe liners are a solution to decrease downtime and increase production due to spillage. The urethane canoe liners are available in 1-in., 2-in. and 3-in. thicknesses, with standard sizes being 7 in. x 48 in., 9 in. x 48 in., and 12 in. x 48 in. ASGCO says the liners can be adjusted up or down to achieve the best fit.

Related: Getting more life out of cone liners