Aggregate producers had plenty to explore on the AGG1 Aggregates Academy & Expo show floor in Nashville this year. Here are a few technologies that came to light at Nashville’s Music City Center.

Next-gen screening

Astec Industries showcased its prototype Vari-Frequency screening technology at AGG1, presenting a solution that will be available on horizontal screens.

Astec’s reimagined screen deck, which the company describes as a “first of its kind,” utilizes a structured frame paired with a live, free-moving deck. The deck harnesses natural frequencies and vibrations that are activated during operation and when material impacts screen media.

Astec says the vibrations stimulate the screen media and bulk material, reducing blinding and boosting productivity.

“Anybody who’s run a screen has had a blinding issue somewhere along the line,” says Stephen Whyte, group vice president of product management at Astec. “This helps eliminate that.”

The Vari-Frequency screen uses side-tensioned screen wire cloth, the company says, and it does not require an external power source. It has common interface points with other low-profile screens.

“We do high-frequency screens,” Whyte says. “We do multi-frequency screens. This would be like the next generation that really takes it to a different level. From one end of the deck to the other, it’s all different frequencies and amplitudes. The impact of material on the deck also affects those frequencies.”

According to Whyte, Astec put roughly 10 years of research and development into its Vari-Frequency technology.

“It’s really been an evolutionary sort of process,” he says.

Elsewhere in screening

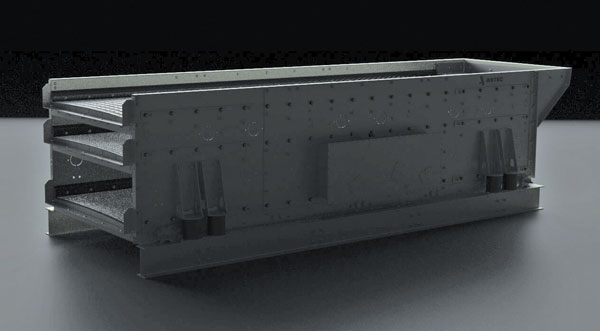

Haver & Boecker Niagara, meanwhile, highlighted its latest screening equipment and technologies at AGG1.

The company displayed its Niagara F-Class vibrating screen, Niagara Drop Guard wear liners, Pulse condition monitoring (CM) and Rhino Hyde liners.

“Haver & Boecker Niagara is dedicated to bringing state-of-the-art innovations to every aggregates operation,” says Karen Thompson, president of Haver & Boecker Niagara. “AGG1 is a great opportunity to connect with industry professionals about not only their operation but the industry as a whole and how our products offer efficient solutions.

The next-generation Niagara F-Class vibrating screen features new tech for simplified maintenance, maximum performance and longevity, according to Haver & Boecker Niagara. The company says the latest design retains the technical benefits of the original F-Class, such as improving performance in material stratification and reducing blinding and pegging.

Additionally, the company provided details about its Niagara Drop Guard wear liners. These are polyurethane liners that provide cross beam protection for Niagara vibrating screens. Haver & Boecker Niagara says they can be installed on an entire screen deck in as few as 15 minutes.

Another development, Pulse CM, is the latest addition to Haver & Boecker Niagara’s Pulse portfolio. The technology monitors the health of vibrating screens using modern algorithms and AI, providing accurate measurements and forecasts that are complemented by easy-to-understand information.

Haver & Boecker Niagara also debuted Rhino Hyde liners at AGG1. Haver & Boecker Niagara acquired partial ownership of Tandem Products, the company manufacturing Rhino Hyde liners, last April. The company says Rhino Hyde liners are lightweight, feature powerful abrasion resistance, and offer reduced maintenance and replacement cost for a range of quarry equipment.