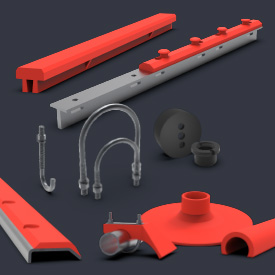

Martin Engineering introduced a modular transfer chute for belt conveyors, reimagining the bulk handling transfer chute to reduce downtime for installation and offer options for future modifications. The new Martin transfer point kit includes modular horizontal loading zone, settling zone and stilling zone configurations. The development provides what Martin Engineering describes as easier installation and a wider variety of chute options while facilitating future upgrades. Martin Engineering’s kit reduces the amount of labor required for assembly and allows the system to be pre-built prior to installation for reduced system downtime.

Updated idler accommodates excessive belt force

ASGCO made improvements to its line of Tru-Trainer dual return conveyor belt tracking idlers. A new design is engineered for heavy-duty conveyor applications with high conveyor belt speeds and tonnages. The updated Tru-Trainer dual return features a lower-profile design for more compact conveyors, with a low height clearance as seen in many conveyor belt feeders and overland conveyor systems. ASGCO says additional improvements are an improved sealing system and simplified roller installation and replacement. ASGCO designed an external central pivot mechanism, obviating the need for a single, large drum while enabling a concentric and balanced rotation to be achieved. This results in extended bearing life and a fast and effective conveyor tracking system, ASGCO says.

Keep tabs on ground-engagement tools on & off machines

GET Trakka provides ground-engagement tool (GET) protection on and off buckets. According to CR, GET Trakka uses embedded sensors and intelligent engineering to provide GET control. The system provides real-time in-cab alarms to ensure operators make effective on-the-spot decisions to reduce catastrophic crusher events, minimize downtime and increase productivity. On the bucket or machine, CR says sensors communicate with a machine gateway to detect if a GET is still locked in position. When a GET goes missing, a portable reader can be activated to rapidly establish the location of the missing component.