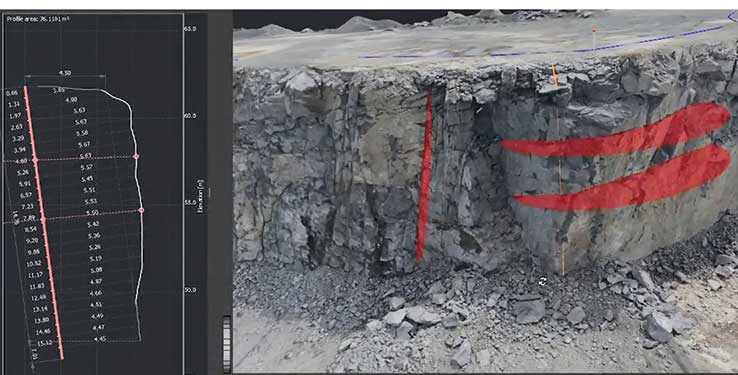

3GSM made several updates to its BlastMetriX UAV software, which is getting service, support and training from R.A. McClure. According to the companies, the new version improves communication with smart drills, offers face profiling enhancements and delivers more sophisticated drill pattern analysis. An enhanced drill pattern analysis tool provides heat mapping of drilled borehole deviations for simple visualization of differences between “as planned” and “as drilled” patterns. Semiautomatic mapping of linear rock mass features is imported into the blast plan. By providing enhanced burden and spacing information, the software allows users to adjust explosive amounts in each borehole to account for irregularities.

Electronic initiation system to power blasting system

Dyno Nobel released its new Ranger electronic initiation system, which will power the DigiShot blasting system. Traditionally, Dyno Nobel says detonators are assigned a hole location only and delay times are set at the time of blast. A flexible tagging option provided by the Ranger system allows for assigning both hole location and delay time at the hole or assigning delay times at any time. This enables users to adjust the process to their needs, speeding up the tagging process. Delay time can also be changed with the push of a button, Dyno Nobel says. Additionally, the Ranger offers a “tag by plan” option that provides a predesigned pattern. Users only need to align the correct hole with the valid hole number on the tagger, reducing the risk of potential user error.

Belt skiver joins product lineup

ASGCO added the Grizzly conveyor belt skiver to its line of conveyor belt products. The Grizzly is a safe and easy way to remove or recess conveyor belt covers in order to install mechanical fasteners, ASGCO says. It is battery operated, featuring dual-acting tungsten carbide blades that accurately skive the rubber off conveyor belt surfaces. According to ASGCO, skived conveyor belts provide for a stronger and longer conveyor belt splice life. The lower profile helps with belt cleaner performance. The Grizzly comes as a kit that is complete with a battery charger, two batteries and a set of tungsten carbide replacement blades – all in a zippered canvas bag.

Parts packages designed for mobile crushers

Sandvik introduced its new Endurance packages of mobile crushing parts, aiming to maximize uptime for customers. Sandvik says the parts in Endurance packages are configurable and can be tailored to meet specific customer needs and requirements. They are designed for sites working long hours or at remote locations where availability and support are essential. According to Sandvik, Endurance packages have all the items needed for repair and maintenance packaged conveniently together, and they’re available in advance for jobsites. The packages range from standard maintenance to major component exchanges, and they’re designed around three main concepts: maintenance, repair and overhaul.

Aiming for a new co-emulsifiers standard

Nelson Brothers debuted NB5-2628 (pictured above at right), a co-emulsifier delivering the formation properties of an SMO (sorbitan monooleate) with far greater synergy, control and stability. NB5-2628 offers an alternative to explosive emulsification processes that utilizes SMO as a co-emulsifier. According to Nelson Brothers, the product pairs rapid formation with superior bulk and packaged emulsion stability – with and without the incorporation of solid dopants. Comparing the shelf life over a 15-month test period, Nelson Brothers says NB5-2628 showed an impressive increase in emulsion stability over an SMO. Additionally, NB5-2628 remained stable in thermal cycling tests with very little crystal formation, whereas the SMO equivalent exhibited significant crystallization in the same conditions.

G Series loaders can now take biodiesel

FPT Industrial, which designs, produces and sells powertrains for on- and off-road vehicles, approved B20 biodiesel for use in its NEF4, NEF6 and Cursor Tier 4 Final diesel engines. FPT made the announcement at the National Biodiesel Conference & Expo, making all Case Construction Equipment G Series wheel loaders approved for use with B20 biodiesel directly from the factory. FPT offered its approval following extensive testing, confirming that the NEF4, NEF6 and Cursor engines performed comparably to the same engines powered by off-road diesel. An FPT study highlighted no adverse effects to engines, Case says. According to Case, B20 biodiesel is the most prevalent blend of biodiesel available in North America. Even with the approval, Case says it is important that all owners of construction equipment consult with their dealer and check their equipment warranty before using biodiesel in machines.