Sulzer Mixpac, a manufacturer and supplier of products and services for liquid application and mixing technology, debuted the Mixpac MixCoat, a cartridge-based portable pneumatic dispense system designed for small volume mining applications, touch-ups and repairs.

Mixpac MixCoat comes in two models: the Spray model and the Manual model.

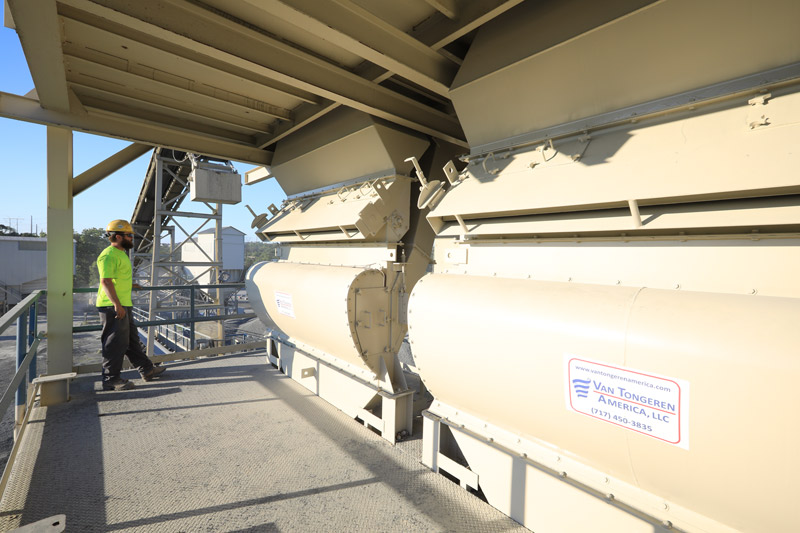

According to the company, the Mixpac MixCoat Spray model can be used for a variety of mining applications, including applying abrasion-resistant coatings on pipes and transportation equipment, bores, walkways and conveyor equipment. In addition, the lightweight system can be set up and broken down quickly, which helps users lose little time during the maintenance cycle.

The system works well with with new abrasion-resistant specialty coatings, including those with glass flake additives. Paired with the DPS Spray Dispenser for maintenance and repair projects, the complete MixCoat Spray system includes cartridges containing the packaged coating material, a mixer that ensures consistent coating mix and the pneumatic operated spray, the company says.

The Mixpac MixCoat Spray system is ideal for one-handed use, and its dials and settings are located on the handle, eliminating the need for additional hoses and gauges, the company adds. With the system, users also have the ability to use 1:1, 2:1, 3:1 and 4:1 ratios by removing the plunger disk and selecting the correct ratio.

Sulzer Mixpac also offers the Mixpac MixCoat Manual model, which is designed for applying high solids epoxies and touchup. According to the company, MixCoat Manual offers efficient, clean and cost-optimized repair work with less waste. The Mixpac MixCoat Manual model does not require pre-mixing or metering of components. It also does not require mixing equipment, the company adds. Cartridges for this model are available for 1:1, 2:1, 3:1 and 4:1 ratios.