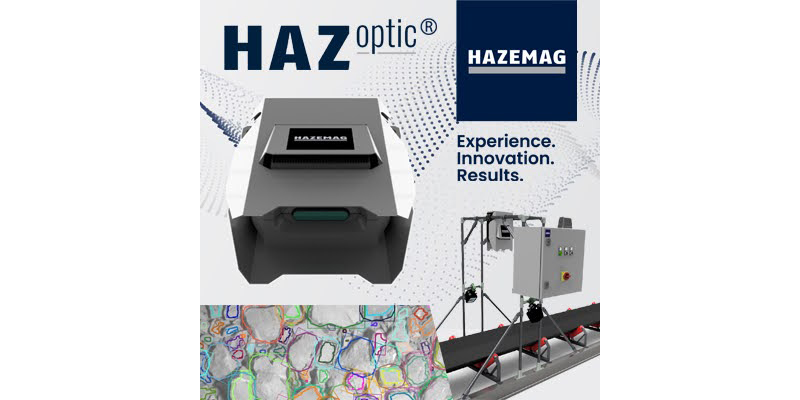

When rock, gravel or aggregate flows through your crusher, every grain matters. The HAZoptic® system from HAZEMAG delivers real time optical sensor monitoring of particle size distribution (PSD) and shape, whether mounted on a conveyor or inside your crushing station.

That level of visibility means instant detection of oversize material, tighter PSD control, and clearer insight into output quality.

HAZoptic® integrates seamlessly with HAZEMAG’s automation suite, giving operators the ability to set quality thresholds, dial in ideal PSD windows, and react quickly to fluctuations through a simple interface.

The result is consistent material, predictable output, reduced waste, and fewer surprises for your operation.