Edge Innovate will showcase its Screenpro S16 scalping screen and introduce the VS750s high-capacity waste shredder at ConExpo-Con/Agg in Las Vegas.

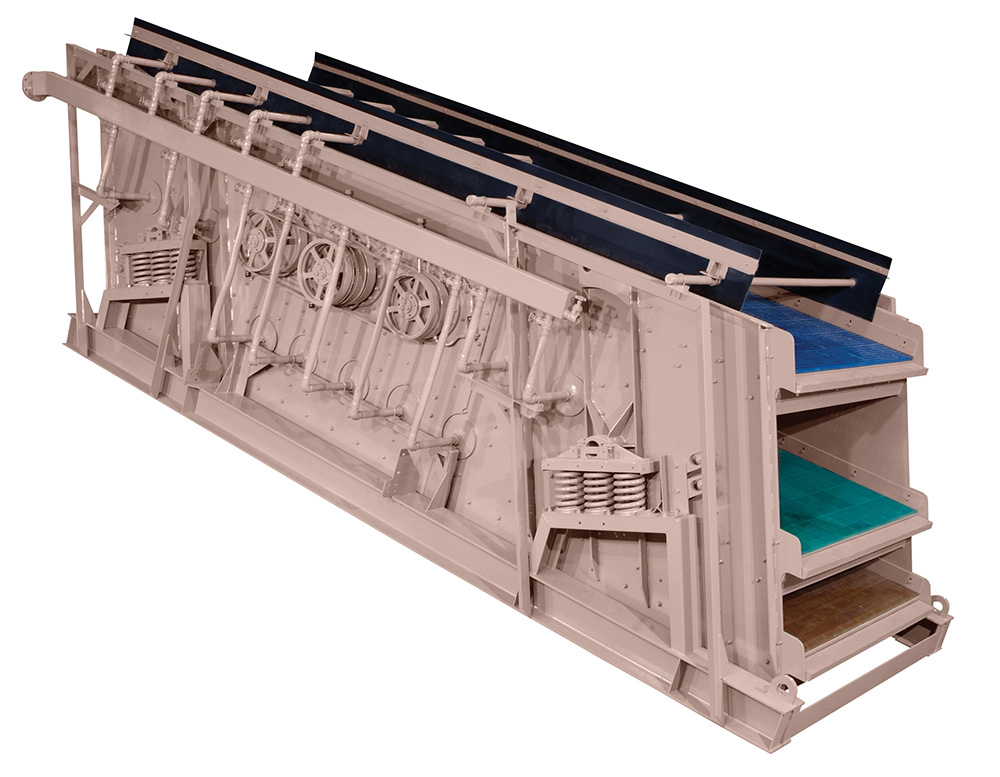

The Screenpro S16, the latest addition to the Screenpro range, is now available to customers across North America. Edge Innovate says the S16 builds upon the success of the larger Screenpro S18 while still emphasizing output, efficiency and versatility.

Designed to handle feed capacities exceeding 650 tph, Edge Innovate says the Screenpro S16 is suitable for mid- to large-scale operations requiring high production rates and precise material separation. The machine features a 16-ft. x 5-ft. dual-deck screen, providing a 16.7-sq.-yd. screening surface. Adjustable screening angles between 14 and 20 degrees, combined with a wide oversize discharge conveyor and heavy-duty feed hopper, allow the S16 to deliver consistent throughput and product quality across a range of applications.

The S16 can be outfitted with multiple screen media options, allowing operators to tailor the machine to suit different materials and end product requirements, whether processing aggregates, construction and demolition waste, or recycled materials. For recycling applications, the S16 can be equipped with over-band magnets and magnetic head drums for ferrous metal recovery.

The S16 incorporates intelligent load management, hydraulic-folding conveyors, a low-level feed hopper and a two- or three-way split configuration. A fully integrated power unit with service access, combined with a control system featuring sequential start-and-stop functionality, enhances productivity and safety, according to Edge Innovate. Maintenance downtime is minimized through a hydraulic lift-up screenbox, enabling fast, efficient mesh changes, supported by full-access walkways on both sides of the machine.

Powered by a Caterpillar Tier 4 Final engine, dual-power and electric-hybrid drivetrains are available for the S16.

VS750s shredder

ConExpo marks the first public appearance of the VS750s, which the company says represents an advancement in slow-speed, high-torque shredding technology. Designed for large-scale recycling and waste processing applications, the VS750s is engineered to process high volumes of waste streams while maintaining control, efficiency and durability.

Weighing just over 59 tons, the machine is powered by a Caterpillar C18 Tier 4 Final engine, delivering the torque and resilience required to sustain demanding, high-throughput operations in the most challenging environments, according to Edge Innovate. The VS750s is available in both direct-drive and electric-hybrid power source configurations, offering flexibility, improved fuel efficiency and reduced emissions.

At the core of the VS750s is a heavy-duty twin-shaft shredding chamber designed to deliver high torque at low operating speeds. This allows the shredder to process materials such as municipal solid waste, construction and demolition waste, green waste, industrial waste, wood and biomass, while producing a consistent output size suitable for downstream processing. Intelligent load management continuously regulates shaft speed and torque to protect the drivetrain, reduce wear and maximize uptime – even when processing highly variable material streams.

“ConExpo is the ideal platform to unveil major new products, and we are proud to introduce both the VS750s and the Screenpro S16 to the North American market and to customers from around the world,” says Darragh Cullen, managing director at Edge Innovate. “The VS750s, in particular, demonstrates our ability to engineer truly high-capacity solutions, combining enormous scale, power and intelligent control in one machine. These products reflect exactly what Edge Innovate stands for: robust engineering, practical innovation and equipment that gives our customers a real operational edge.”

Related: Latest cutting-edge equipment