Keestrack will showcase several pieces of equipment at ConExpo-Con/Agg, March 3-7 at the Las Vegas Convention Center.

The company will be located in the Central Hall (Booth C31641). On display at Keestrack’s booth will be the K6 scalper, B4 jaw crusher and R5 impact crusher.

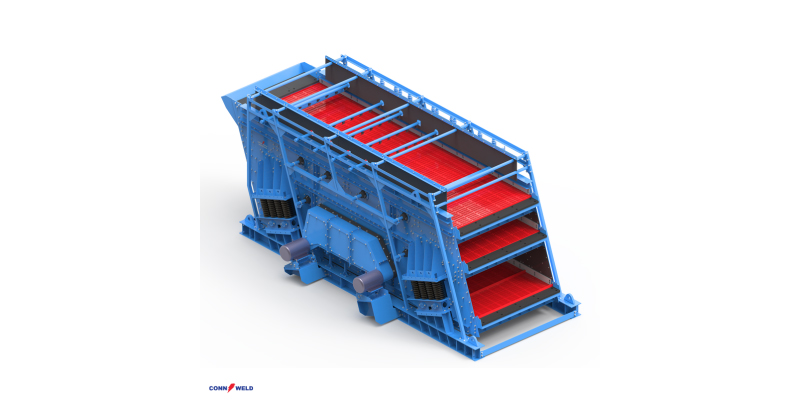

K6 scalper

This year, Keestrack celebrates 30 years of scalping technology with the K6 scalper.

The K6 is equipped with a heavy-duty plate apron feeder, hydraulically folding hopper walls, load-sensing hydraulics and a long, wide screening deck. The K6 is suited for applications ranging from coarse scalping to fine screening.

At ConExpo, Keestrack will present the K6 in a special anniversary livery.

B4 jaw crusher

Keestrack says its B4 jaw crusher is engineered for heavy-duty recycling applications. Its Non-Stop System with hydraulic gap adjustment automatically opens the crusher when uncrushable material enters the chamber and then resets itself hydraulically. During operation, the closed side setting is continuously monitored and automatically adjusted to ensure consistent, high-quality output.

The B4 features a heavy-duty hopper with hydraulically folding hopper walls and a secure locking system, allowing easy loading by excavators or wheel loaders. The vibrating feeder automatically regulates the feed to maintain a crusher load of approximately 80 percent.

An independent two-deck prescreen delivers crushing capacity of up to 400 tons per hour while reducing wear, Keestrack says. Prescreened fractions can bypass the crusher or be stockpiled separately using the optional side conveyor.

The B4 has a feed opening of 43 in. x 27.5 in. and accepts feed sizes up to 24 in. The closed side setting ranges from 1.75 in. to 6.33 in., even with worn jaws. Automatic wear compensation is activated every 50 operating hours to maintain consistent end-product quality, with manual adjustment available if required.

Walkways, doors and panels on all sides of the machine simplify maintenance, according to Keestrack. The hydraulic sliding hopper frame further improves access beneath the feeder and scalping unit.

The B4 is available in three drive versions: diesel-hydraulic, hybrid plug-in and ZERO full-electric drive.

R5 impact crusher

The R5 impact crusher combines reliability, compact dimensions and high productivity, according to Keestrack. The machine is transportable as one complete unit, including a double-deck after screen and can be set up quickly without support legs.

The R5 offers crushing capacities of up to 350 tph, delivering a cubical end-product with reduced wear thanks to its independently driven two-deck prescreen. Keestrack says this makes the R5 suitable for applications in recycling, aggregates, quarrying and mining.

A swiveling oversize return conveyor can be converted into a stockpile conveyor within minutes. Optional features such as a two-deck after screen, wind sifter and magnetic separator allow the R5 to function as a complete mobile processing plant.

The R5 is available in diesel-hydraulic or full-electric plug-in versions. The electric model includes a plug-out connection to power additional equipment and can be operated either with an onboard diesel generator or as a ZERO drive, without any combustion engine on board.

Related: Keestrack taps Romco as Texas dealer