Custom portable screen delivers precision in tough conditions

General Kinematics’ portable horizontal screen is a solution for on-the-go screening. Designed for flexibility, the company says its rugged machine adapts to specific material and processing needs. The portable horizontal screen is customizable and built to endure tough conditions, delivering precision performance wherever the job takes operators.

Screen panel boosts throughput with lightweight, durable build

Metaldex XPT closes the gap for producers stuck between wire cloth and cast-molded panels that do not offer enough open area. According to Polydeck, Metaldex XPT features abrasion-resistant welded wire that’s engineered for aggressive dry sizing. Its lightweight, 1-ft. x 2-ft. design offers faster changeouts and may help reduce injuries, and it features polyurethane-encased construction for stability and safety during high-vibration screening. Polydeck offers Metaldex XPT as a solution for coarse sizing applications where durability and open area matter, offering up to 63.8 percent open area for high-volume sizing and available in multiple thicknesses and configurations for different material flow paths.

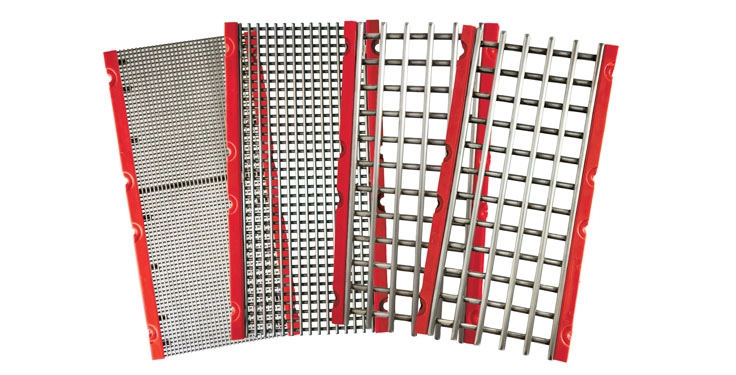

Durable solutions with precision openings

Conn-Weld Industries’ Tuff-Wire is assembled using a fusion welding process known as Tuff-Screens. The company introduced the process in 1975, with a variety of options offered in the line today. Tuff-Wire features a range of openings down to the smallest aperture of 1/8 in. Urethane edging is available in various thicknesses. Additionally, Conn-Weld’s Tuff-Plate is available in slotted, squared, round angled and octagon openings.

Redesigned plant boosts mobility, access and stockpiling

The M515 is ideal for creating riprap and recovering rocks mixed with clay and other sticky materials, according to MDS. The M515 was recently redesigned to include features that improve transportation, access and stockpile heights. An enhanced engine includes a swing-out feature and a swing-out access platform that makes access to the cabinet easier. The engine was also relocated to the side of the unit, enabling customers to fit the unit on smaller bed trailers in North America and lower their transportation costs. The fines and mid-product conveyors were made longer to increase stockpile heights, MDS adds.

Scalper offers easy transport, high-capacity screening

The Trident 165 is the latest version of Screencore’s flatbed scalping screen. According to Screencore, the new plant includes features designed to aid performance – including easy transport, quick setup and intuitive control systems. The double-deck scalper features a 16-ft. x 5-ft. top and bottom screen. The full-size top and bottom decks ensure no loss of production due to a smaller bottom deck. Powered by a Cat C4.4/3.6 engine, Screencore says the Trident 165 is engineered for heavy-duty applications and is available with an apron feeder for super-duty operation.

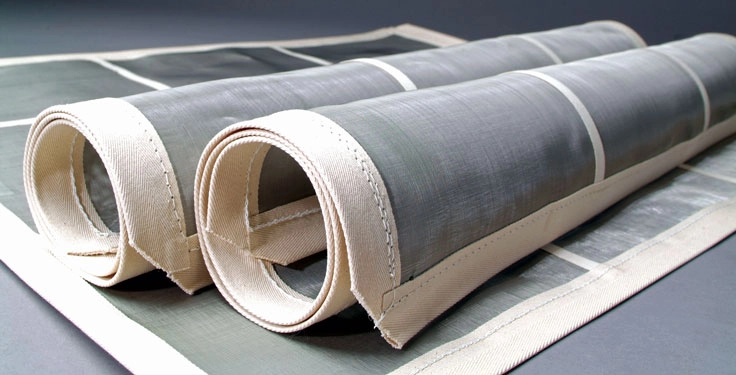

Custom-fabricated edge screens for industrial applications

Compass Wire Cloth offers custom-fabricated edge screens for demanding environments. Built for precision and durability, Compass Wire Cloth says the screens are engineered to meet exact OEM specifications while enhancing efficiency across a range of industries. Each screen is constructed with stainless steel, carbon steel or synthetic mesh options such as polyester and nylon. The edge types are diverse, ranging from bonded and polyester to high-temperature Nomex, vinyl and heavy-duty metal edges to ensure compatibility with different processing applications.

Related: The latest in available equipment