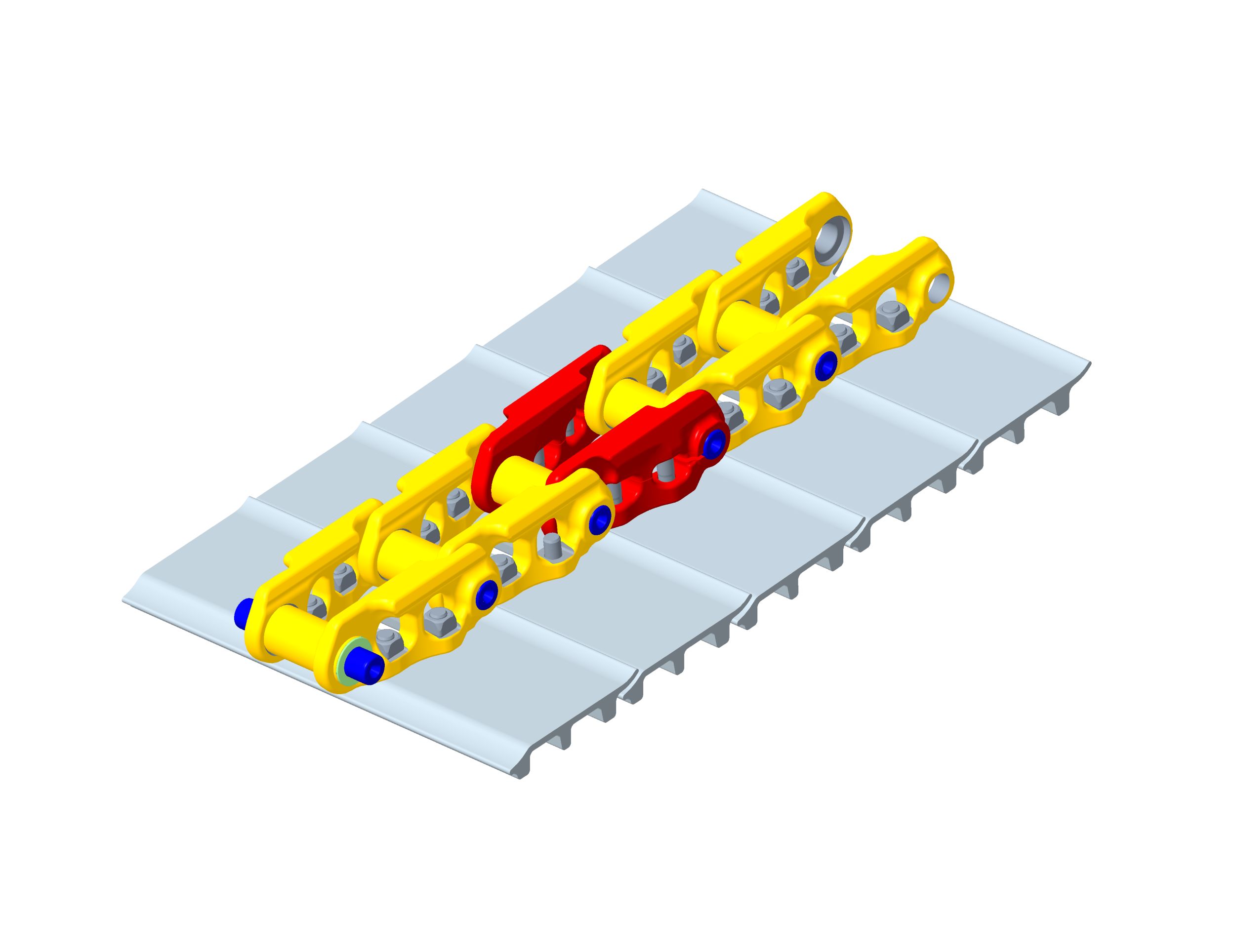

Caterpillar introduced the track clamp master link to improve track installation efficiency in the field by eliminating the need for a portable field press.

The new track clamp master link, which replaces both slip-style and press-fit joints, requires no hydraulic tooling or presses, allowing operators to safely remove and install tracks without additional equipment.

“Improperly managed undercarriages cause downtime and cost money,” says Tim Nenne, senior market professional at Cat. “The track clamp master link is available for any standard hydraulic excavator with a 7.5-in. pitch size class, making in-field track installation both simple and safe.”

The track clamp master link is used across a variety of hydraulic excavators and covers all types of undercarriages – including general duty, heavy duty and heavy duty XL. It’s currently available on the Cat 320 excavator, with more models to come in 2026.

“We all know how time-consuming both slip-style and press-fit joints can be to replace, but after all that effort, they’re not infallible either,” Nenne says. “Caterpillar focused on durability when developing the new link, making durability a feature alongside convenience, speed and safety. Extensive press-out testing has shown that the track clamp master link offers 25 percent higher pin retention compared to the press-fit master and up to a 50 percent improvement in joint life compared to the slip-fit master.”

Related: Cat adds comfort, control to articulated truck lineup