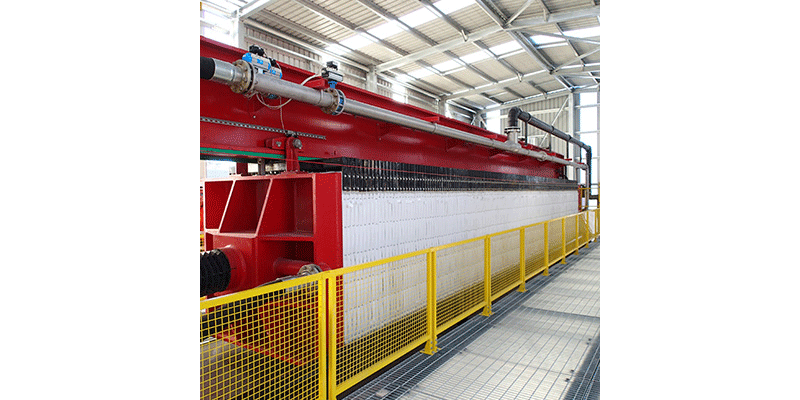

McLanahan Filter Presses deliver the perfect balance of performance and efficiency, helping operations turn slurry into easily managed dry material while reclaiming valuable clean water. Engineered with a streamlined single-cylinder design, they provide reliable automation with less complexity, lower energy use and faster cycle times. Whether in tailings, concentrates or modular applications, McLanahan’s Overhead and Side Beam styles ensure superior cake release, easy maintenance access and transport flexibility. Backed by expert testing, responsive service and remote monitoring capabilities, McLanahan Filter Presses keep plants running profitably around the clock.

One of the most significant causes of downtime in Filter Press operation is the replacement of filter cloths. Minimizing this maintenance time can deliver an estimated 4–6% increase in uptime. The patents-pending QUICKCHANGE™ system, developed jointly by McLanahan Corporation and Diefenbach, is revolutionizing filter press maintenance. This rapid-change technology simplifies filter cloth replacement and plate inspection, enabling operators to maximize efficiency and reduce downtime across their sites.