Slurry pump range adds two new sizes

Sulzer expanded its EMW heavy-duty slurry pump range with two new high-capacity sizes. The EMW series is engineered to deliver superior reliability and low total cost of ownership, according to Sulzer. The new sizes continue the range’s tradition of extended pump service life and optimized hydraulics at reduced energy use. Spare part consumption is kept at a minimum, the company adds, and standardized components result in lower spare part costs. With the expansion, Sulzer says the EMW series now offers a robust alternative for a slurry pump when performance, durability and serviceability are nonnegotiable.

Double diaphragm pump operates with smaller footprint

ARO’s EVO 210 electric double diaphragm pump is engineered to provide enhanced efficiency and savings – especially in applications where compressed air is not an available resource or higher efficiency is desired. ARO says its new model strikes a balance between performance and simplicity, ensuring a cost-effective diaphragm pump solution without compromising on reliability. The pump’s design facilitates a smaller overall footprint, ARO says, with a simple yet robust drivetrain that optimizes the number of components. Additionally, ARO says the pump’s diaphragm orientation allows for quick and easy maintenance to maximize operational uptime.

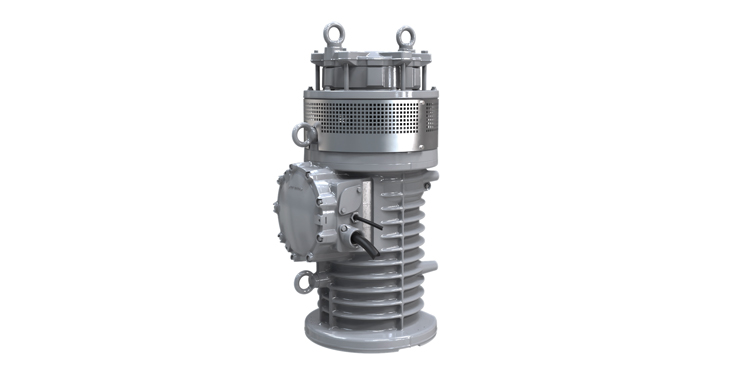

Pair of new pumps suitable for mining applications

Xylem launched the Flygt 2450, a submersible pump for mining applications that the company says eliminates the need for extra infrastructure to handle abrasive water. According to Xylem, the pump reduces wear and extends the time between servicing for up to 6,000 hours. This is achieved through the inclusion of a Hard-Iron hydraulic end and Dura-Spin diffuser technology. Building on this, Xylem also introduced the Flygt 2401, a redesigned version of the Flygt 2400 submersible pump. This model offers flexibility in mining applications with two hydraulic configurations: one optimized for high head lifting and the other for high-volume flow.

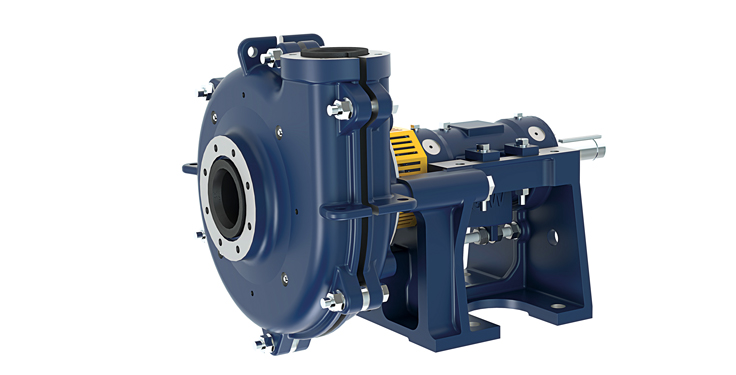

Upgraded pump series builds on performance of original line

KSB GIW launched the GIW LCC Gen2 slurry pump series, a redesigned and upgraded version of its GIW LCC line. Designed for Class 1 to 3 slurry applications, the company says the GIW LCC Gen2 maintains proven hydraulic performance while adding a modern design that improves maintenance access, extends service life and lowers total cost of ownership. The GIW LCC Gen2 series retains the hydraulic performance of the first-generation GIW LCC while introducing upgrades in serviceability, reliability and spare parts compatibility. The new pumps will roll out in phases across North America.