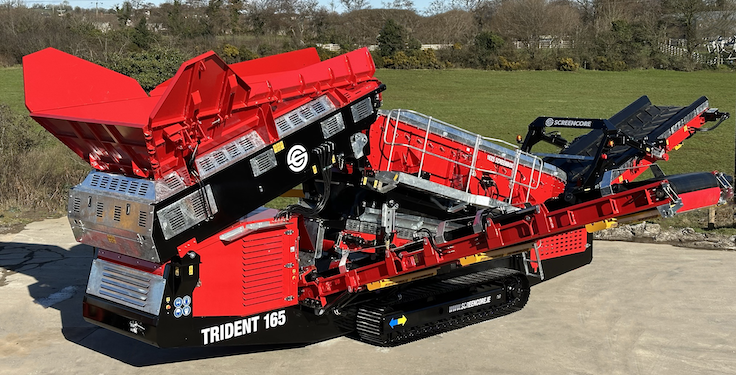

Screencore introduced the Trident 165, the latest version of its flatbed scalping screen.

According to Screencore, the new Trident 165 includes features designed to aid performance, including easy transport, quick set-up time and intuitive control systems.

“All our products include distinctive design elements, such as full-sized bottom decks on scalpers or augers within the trommel hoppers,” says Ciarán Ryan, director at Screencore. “When we build a screen or crusher, we make sure that our customers are at the heart of our design process. This is evident with the newly redesigned Trident 165, which has been developed through close contact with our customers and distributors. As we’ve grown, we’ve learnt a lot, and this has been channeled into the latest iteration of the Trident 165.”

The latest Trident 165 is a double-deck scalper with a 16-ft. x 5-ft. top and bottom screen. The full-size top and bottom decks ensure there is no loss of production due to a smaller bottom deck. Powered by a Cat C4.4/3.6 engine, Screencore says the new Trident 165 has been engineered for heavy-duty applications and is available with an apron feeder for super-duty operation.

“Although the original Trident 165 proved highly effective and popular, the redesign enables us to ensure that the Trident 165 truly represents such core Screencore features as versatile power options for a greener future, thereby helping our customers work towards the circular economy,” Ryan says. “This includes full dual-power, which enables the unit to provide auxiliary electric or hydraulic power for a downstream stockpiler.

“The new version of the Trident 165 represents the culmination of several years of customer feedback and extensive research to incorporate the best features demanded by customers from a mid-sized scalping screen,” Ryan adds. “We have taken the feedback on board to produce what we believe is a game changer.”

Weighing just under 64,500 lbs., the new Trident 165 features a 10-cu. yd. hopper with impact bed, a 55-in. wide four-ply feed belt and 3-ft. wide side conveyor belts on telescopic extending conveyors. Additionally, the machine includes 13 ft. tracks with a 20-in. shoe, walkways on both sides and radio remote control.