Conveyor systems are the backbone of the aggregate industry, moving stone, sand, gravel and other materials across vast distances with relentless efficiency.

Within every conveyor lies a critical component often overlooked until failure strikes: the idler. Engineered for durability, modern idler designs must withstand punishing environments filled with abrasive dust, moisture, heavy impacts and challenging maintenance conditions.

For producers focused on uptime, performance and safety, choosing the right idler is no longer a routine decision. It is a strategic one.

Idlers in quarries

Quarry applications are notoriously harsh. Fine silica dust, moisture from washing operations and rainfall, and constant vibration from large, uneven material all conspire to degrade conveyor components over time.

Idlers in these settings are particularly vulnerable to:

- Dust ingress. Fine, abrasive particles infiltrate poorly sealed bearings and act like sandpaper, accelerating wear and causing premature failure.

- Moisture intrusion. Exposure to rain and washdown, or other persistent forms of moisture, leads to corrosion and grease breakdown inside the bearing cavity.

- Heavy impact loading. Larger stone and aggregates often impact the belt near loading zones, transmitting shock loads through the idler roll and into the bearings.

These environmental factors demand a higher standard in idler design, especially in sealing, materials and bearing selection.

Impact idlers

One of the most punishing areas in any quarry conveyor system is the load zone, often referred to as the transfer point, where large, heavy stone and aggregates are dumped onto the belt from other conveyors, crushers, hoppers or loaders. These zones are subject to intense impact forces that, if not properly managed, can lead to belt damage, structural fatigue and rapid idler failure.

Impact idlers are engineered specifically to absorb and distribute these forces. Unlike steel trough idlers, impact idlers incorporate rubber discs or resilient cushioning rings between the steel roll body and the belt. These components deform slightly under load, absorbing the shock of falling material and reducing the transmitted force to the belt and frame.

Some of the benefits impact idlers provide in aggregate operations are extended belt life by reducing localized stress and abrasion, protecting frame structures from repeated impact fatigue, reduced risk of shell denting and bearing misalignment, and improved system reliability in critical zones like crushers, load points and transfer stations.

By incorporating impact idlers at all key loading zones, producers can prevent many of the failures caused by heavy impact loading. This targeted protection is essential for maintaining overall conveyor health and ensuring the longevity of downstream idlers and components.

Advanced sealing systems

The most effective way to extend idler life is by keeping contaminants out. High-performance idlers now feature multi-stage sealing systems specifically developed for aggregate environments. These typically include:

- Stone guards to block large particles and deflect direct impacts

- External polymer wipers to sweep off fine dust and moisture

- Grease-filled labyrinths to trap contaminants within multiple channels

- Internal contact seals to create a final, tight barrier

- Retaining rings to hold the sealing and bearing assembly in place, even during high-speed or off-center loading

Together, these components form a sealed system that can operate for years without maintenance – even under continuous exposure to harsh quarry conditions.

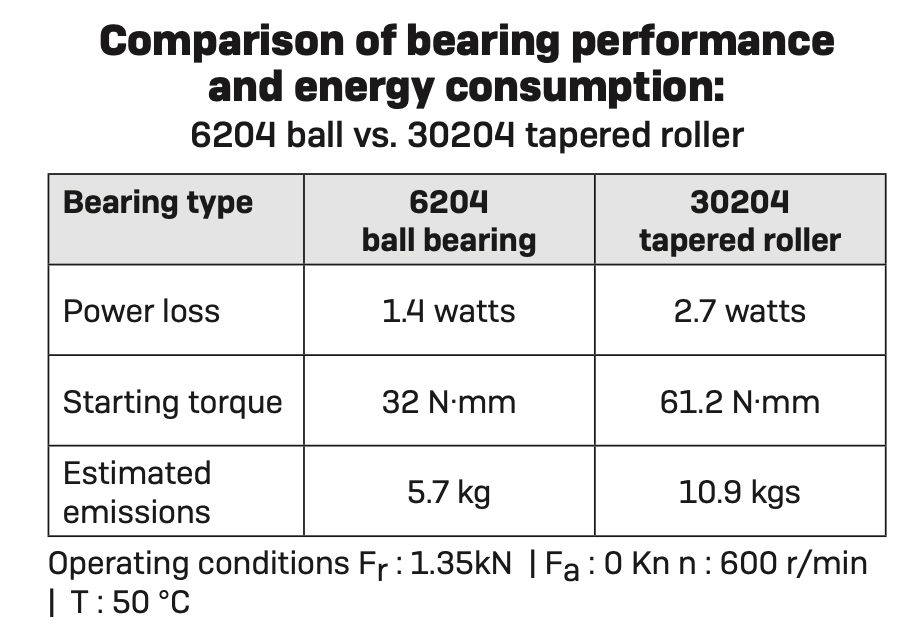

Ball versus tapered rollers

One of the most important choices in idler design is the bearing type. While both ball bearings and tapered roller bearings are used across industries, aggregate operations have proven that sealed-for-life ball bearings are the superior choice for most applications.

Ball bearings offer several advantages:

- Point contact design reduces the surface area exposed to contaminants.

- Factory-sealed construction eliminates the need for periodic greasing – a major advantage in hard-to-reach locations or where maintenance resources are scarce.

- Simplicity and durability mean fewer moving parts, reduced misalignment issues and better performance under shaft deflection.

- Lower sensitivity to debris compared to tapered rollers, which have larger contact areas and rely heavily on pristine lubrication conditions.

In aggregate operations where contamination is inevitable, ball bearings consistently outperform tapered rollers, particularly in the CEMA B through E+ idler classes.

Ball bearings reduce rolling resistance and improve energy efficiency by minimizing friction through a point contact design. Their performance remains consistent in dusty, high-impact environments, where tapered rollers are more prone to drag and misalignment.

This reduction in friction also lowers energy consumption and carbon dioxide emissions per ton conveyed, supporting both cost savings and sustainability initiatives.

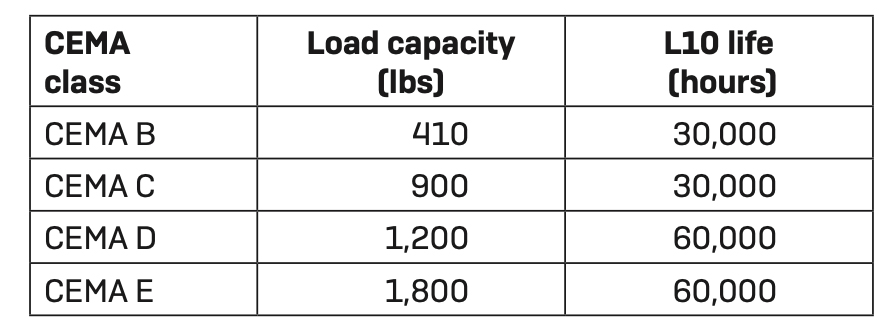

Understanding CEMA classes

The Conveyor Equipment Manufacturers Association (CEMA) classifies idlers by load capacity and expected bearing life (L10 rating). This helps operators select components that match their duty cycles and belt configurations. In aggregate operations, it is important to match the idler class to the application.

For instance, CEMA C idlers may work well in most applications, but high-impact zones such as near crushers, screens or surge piles often require CEMA D or other solutions. Selecting the wrong class can result in accelerated bearing failure, excessive belt wear and costly, unscheduled downtime.

In the unpredictable world of aggregate production, downtime is a cost few can afford. That’s where CEMA-standardized idlers prove invaluable.

Built to uniform dimensions, load ratings and bearing types, CEMA idlers offer complete interchangeability between manufacturers – making replacement fast and supply chains more reliable.

For operators managing multiple sites or relying on distributor networks, this standardization provides easier sourcing of replacement parts in emergency or high-wear situations, simplified inventory management, faster installation with consistent dimensions across idler classes, and confidence in load ratings and service life tied to published industry standards.

CEMA compatibility also supports better energy efficiency. Mismatched or non-standard idlers can cause belt misalignment, increased rolling resistance and belt drag, wasting horsepower and increasing energy consumption and operating costs.

Using standardized, high-efficiency ball bearing CEMA idlers ensures smoother operation, especially when compared to tapered bearing units that are more sensitive to misalignment and lubrication issues.

Where tapered roller bearings require perfect alignment and optimized conditions to perform efficiently, sealed-for-life ball bearings used in most CEMA idlers maintain consistent, low-friction rotation even when conditions are less than ideal. This improves energy usage per ton moved and reduces the risk of sudden failure from contamination or lubrication breakdown.

Modern idlers are CNC-machined to tight tolerances, which contribute to minimized runout for smoother operation and reduced rolling resistance, reduced vibration and even load distribution across all bearing elements.

This precision not only extends bearing life but improves energy efficiency and belt longevity – key considerations for producers focused on cost per ton.

Counter bored tubing

One often-overlooked feature that contributes significantly to idler performance is the use of counter bored tubing. In aggregate environments where impact and vibration are routine, this design detail ensures better alignment between the shaft and tube, minimizing internal movement that can lead to premature failures or seal wear.

By creating a machined seat for the bearing housing, counter boring reduces axial play and ensures concentricity throughout the roll’s rotation. This leads to:

- Improved sealing performance by keeping components aligned

- Better total indicated runout, which extends bearing life

- Lower vibration, enhancing belt tracking and structural integrity

- More consistent energy efficiency across the conveyor system

In high-speed or high-load operations typical in quarries, even slight misalignments can multiply energy losses and maintenance issues. Counter bored tubing provides a solid mechanical foundation for long-term performance and reduced total cost of ownership.

Final thoughts

Quarries and aggregate producers demand more from their conveyor systems than ever before. With tighter margins, rising labor costs and a relentless push for uptime, idlers must be engineered not just for rotation, but for resilience.

Advanced sealing systems, optimized ball bearing designs and precision manufacturing have ushered in a new era of reliability. By selecting idlers purpose-built for dusty, wet and impact-heavy environments, producers can extend service life, minimize maintenance and improve overall conveyor system performance.

The return on investment is clear: fewer changeouts, less unplanned downtime and improved belt health across the entire conveying system. Operators who treat idlers as critical engineered components rather than commodity items gain measurable advantages in system efficiency and long-term cost control.

In today’s high-output quarries, every ton counts, and dependable idler performance is a key part of keeping that tonnage moving.

Paul Ross is president and CEO of Douglas Rulmeca and Simone Costa is corporate engineering manager at Rulmeca Holding.