VDG (Van der Graaf) celebrated its 40th anniversary with an open house at its facility in Shelby Township, Michigan.

Media members and company employees were on hand to celebrate the milestone. VDG provided tours of its manufacturing operation, highlighting its in-house engineering, CNC machining, automated production and precision gear cutting.

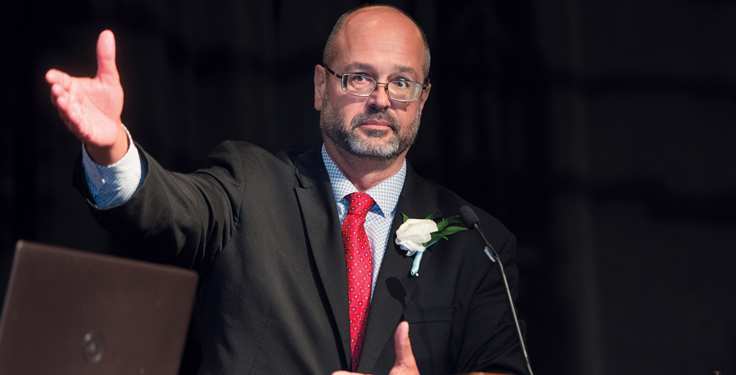

“VDG has spent the last four decades pushing the boundaries of reliability and performance in motorized pulley systems,” says Alex Kanaris, president of VDG. “We’re proud to be manufacturing the VDG drum motor here in North America – and especially in the great state of Michigan.”

Kanaris founded VDG in Canada in 1985. The company established a U.S. operation in 2003 and opened its first service and assembly plant in Shelby Township in 2010.

From there, the company opened a full-scale manufacturing facility in 2018 and a second facility in 2023.

During the event, Kanaris addressed attendees and thanked everyone who helped make the last four decades possible.

“This company was not built on its own,” Kanaris says. “I had a lot of help. The main help I had was from my wife (Sonia) and my boys (Jason and Dimitri). They supported me and put up with me traveling. I had their full support.

“Also, [I want to thank] the employees who have brought us here,” he adds. “The majority of our employees started here 30 to 40 years ago – and they’re still here.”

Kanaris says VDG’s mission continues to be customer- and employee-driven.

“About 20 years ago, we paid someone to wordsmith a mission statement,” he says. “We plastered it in our lobby. Every time I walked in and read it, I had no idea what it meant, so I took it out.

“My mission statement is very simple: Customers come first, employees come second, I come third,” he adds.

The open house was also an opportunity for VDG to showcase its American-made, self-reliant manufacturing capabilities. As Kanaris put it, the only components the company buys are steel, tubes and shafts.

This in-house manufacturing played a key role in keeping lead times short during the COVID pandemic – and it continues to be a source of pride for VDG.

Currently, every component of the VDG drum motor is manufactured at the company’s Shelby Township facility, according to the company.

“We are a very autonomous company,” Kanaris says. “Of course, we’re not the least expensive in the industry but we think American, buy American and employ American. That’s our motto.”

Having already invested more than $50 million in outfitting its Shelby Township facility with advanced production technology and hiring local talent, Kanaris says there is still room to grow.

“We have plans for growth,” he says. “We grew from 3,500 sq. ft. to [300,000 sq. ft. between] this facility here and the facility in Toronto. That’s not going to stop. We’re going to keep on growing.”

Building the brand

Looking back over the last 40 years, Kanaris has seen and experienced a lot. In that time, he and VDG have had a first-hand look at – and contributed to – the growth of the drum motor industry in the U.S.

“When I started manufacturing drum motors, there was no drum motor market in the United States,” Kanaris says. “In the aggregate industry, nobody knew what a drum motor was. We didn’t only have to design and manufacture a product; we had to sell the product.

“It’s been an uphill process for us, but we were very persistent and did extensive advertising,” he adds. “Advertising and adhering to engineering principles for our designs and manufacturing got us to where we are.”

Related: How Peckham Industries is utilizing a unique drum motor