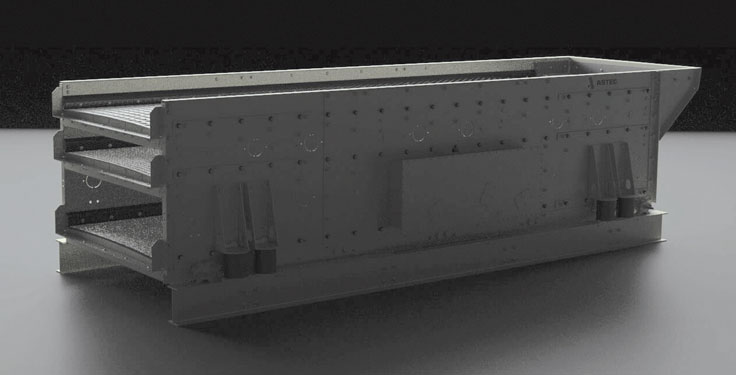

Self-cleaning tech boosts performance, lowers costs

Astec Industries’ Vari-Frequency screen technology offers increased performance and reduced operating costs. Utilizing standard, side-tensioned screen wire cloth, the company says functionality is achieved through a deck that generates multiple vibrations throughout the length of the screen. Self-cleaning technology eliminates the need for manual cleaning. Astec adds, with the technology not requiring an external power source. The company says the screen has common interface points with other low-profile screens for easy replacement.

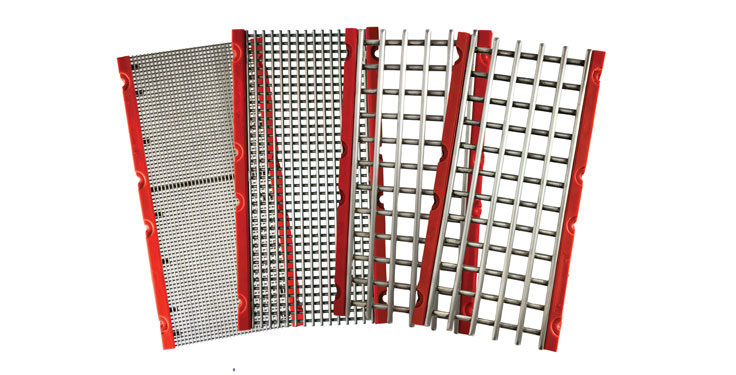

Durable solutions with precision openings

Conn-Weld Industries’ Tuff-Wire is assembled using a fusion welding process known as Tuff-Screens. The company initiated the process in 1975, with a variety of options available in the line today. Tuff-Wire features a range of openings available down to the smallest aperture of 1/8 in. Urethane edging is available in various thicknesses. Additionally, Conn-Weld’s Tuff-Plate is available in slotted, squared, round angled and octagon openings.