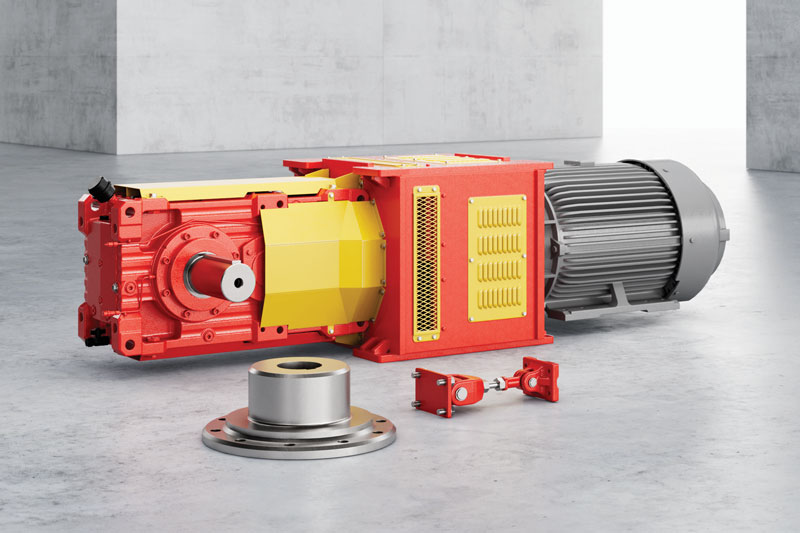

SEW-Eurodrive’s XMiner industrial gear units are built for the toughest mining and aggregate applications. Designed on the X.e series platform, the company says XMiner delivers high torque, reliable performance and easy installation with a plug-and-play design. Featuring cooling, reversible housing and a taconite sealing system, XMiner ensures durability in harsh conditions. Assembled in South Carolina with local support and global service, SEW-Eurodrive says XMiner minimizes downtime while maximizing efficiency.

Intelligent breather made for gearboxes

Dodge Industrial’s Optify breather is an intelligent desiccant breather allowing customers to tap into its condition monitoring platform. According to Dodge, Optify users can now remotely monitor breather status to extend gearbox life and streamline maintenance. The breather features sensor technology, providing precise data measurements and key performance indicators such as breather life, rate of saturation, internal gearbox headspace temperature, battery life and saturation direction. Dodge says the breather is compatible with the Optify platform out of the box, allowing users to review asset status quickly, compare like-asset data and analyze historical trends.

Solution to monitor machine health

Regal Rexnord Corp.’s next-generation Perceptiv intelligent reliability and maintenance solution is for condition monitoring and predictive maintenance in industrial manufacturing. The next evolution of the Perceptiv ecosystem offers users a unified platform to meet growing reliability needs, the company says. Perceptiv intelligence uses in-field sensors and gateways to monitor machine health. The collected data can be sent to a customer’s on-premises system through industrial protocols or to the Perceptiv web platform for online viewing. Through the web platform, Regal Rexnord reliability engineers can analyze the data to provide customers with recommendations on how to extend equipment life and reduce unplanned downtime.